back to overview

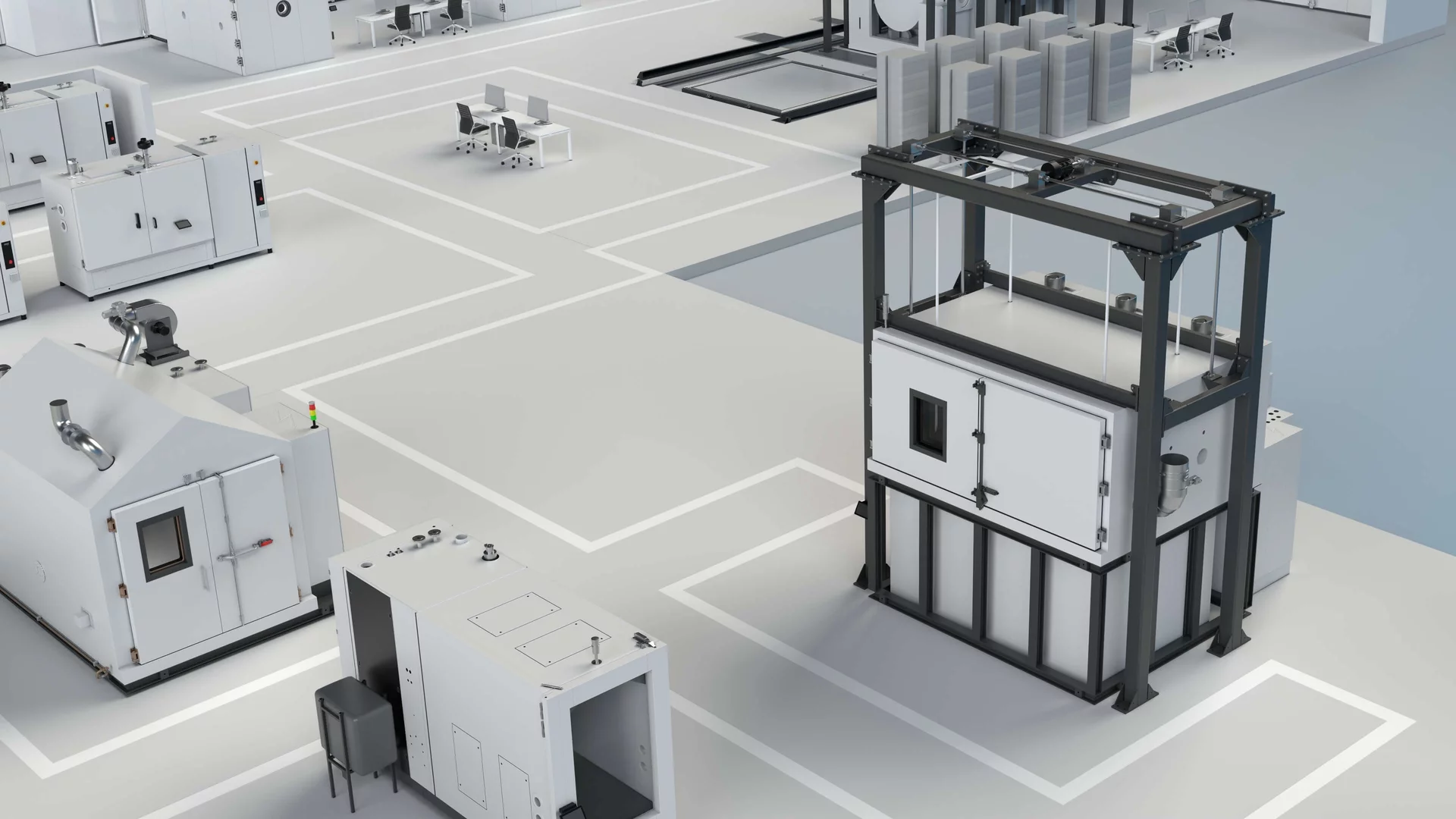

AIR-ICE WATER SHOCK TEST

In the demanding tests, the test material is first heated to 60 to 90 °C and then shock-cooled by rapid immersion in 0 °C cold water. A test series consists of 20 cycles with five minutes of immersion time each. As the ice water must have a salt content of 5%, the test system is corrosion-resistant. The test room consists of an approx. 10 m³ air tempering area with a fan unit and an 11.7 m³ ice water basin below. Complete battery packs weighing up to 800 kg can be tested in the system.

Watch impressions