With more than 14,500 employees around the world, WACKER CHEMIE AG is one of the innovation and technology leaders for specialist chemical products. One important area of work is the development and optimisation of primary products and recipes. Testing under certain climatic conditions is a central step within the development process. For this reason, WACKER relies on tried-and-tested and versatile

Stimulating industry for 80 years

With 23 production locations around the world, more than 3,200 products and a turnover of about 5 billion €, WACKER CHEMIE AG is represented in almost all relevant key industries. One important area is the construction industry, for whom WACKER develops tile adhesives, paints and plaster, self-spreading compounds, thermal insulation systems, waterproofing slurries, adhesives and bitumen coating. WACKER works closely with its customers in order to reliably achieve the required product properties and check these in series of tests.

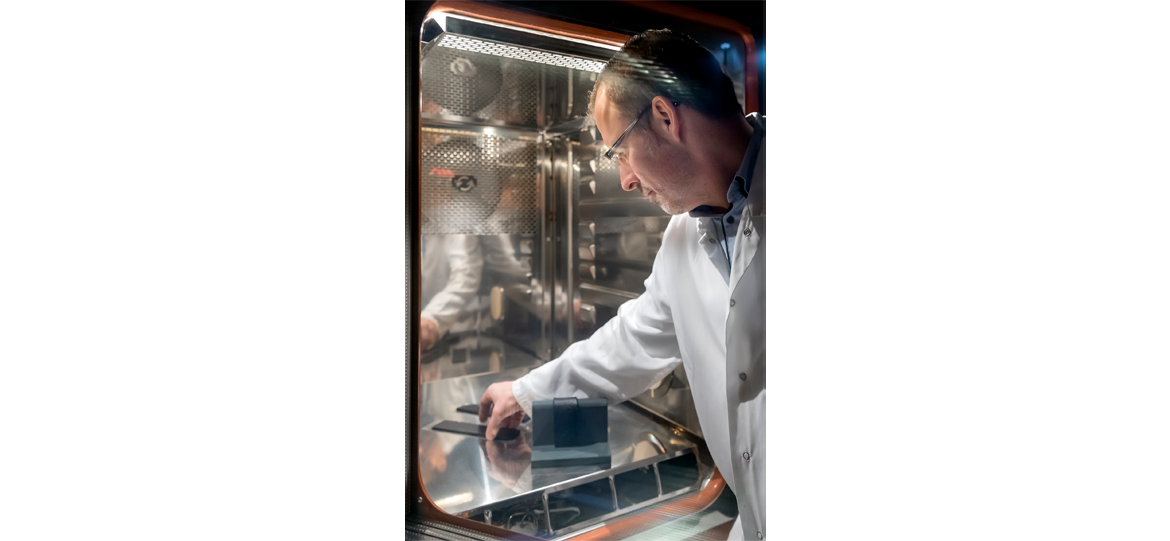

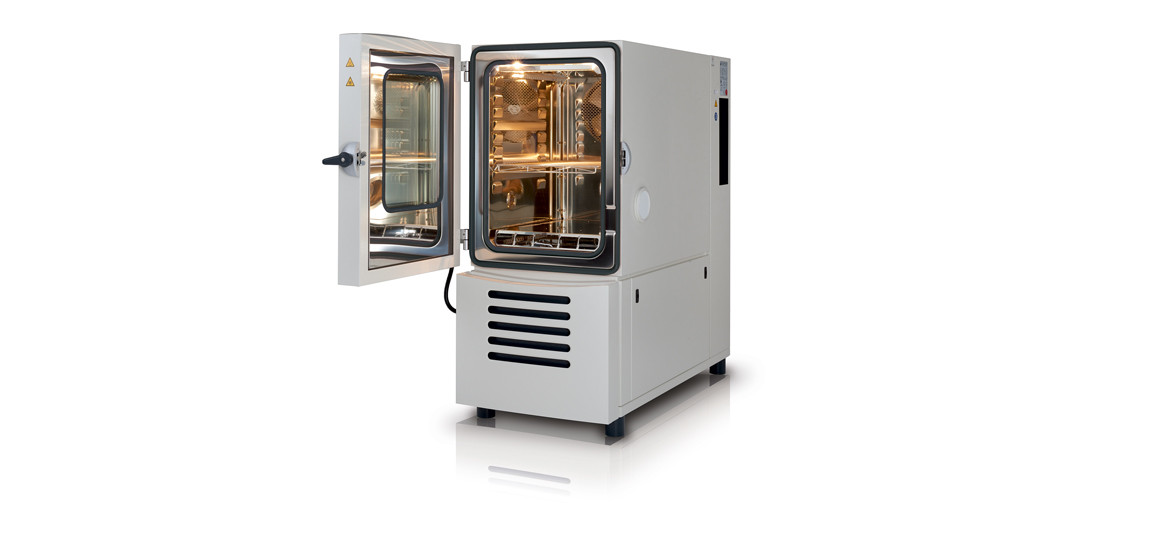

Central testing equipment for eight laboratory groups

At company headquarters in Burghausen near Munich, eight laboratory groups access the test laboratory testing technology. Among other things, this comprises a total of six weisstechnik standard climate test chambers and a special test chamber for larger test specimens. In addition, the location has a complete climate laboratory from weisstechnik. Here, applications can be tested under a wide range of realistic climatic conditions. It is possible to test, for example, how a bitumen mass can be processed at + 40 °C and 90% humidity in Dubai, or whether cracks appear in the same mass at - 20 °C in Moscow. This represents an enormous cost advantage, significant time saving and reliable way of achieving reliably comparable test results.

Testing technology from the inventor of environment simulation

WACKER specifically release on testing technology from weisstechnik for the tests. On the one hand because they can precisely achieve the required climatic conditions – generally temperature and humidity. On the other because the devices and chambers work extremely reliably and are ready for use again quickly following maintenance. Michael Killermann, application engineer at WACKER: “We are extremely satisfied with the equipment and the service is perfect. On the rare occasions that intervention is necessary, the technicians always know what to do and get the system up and running again quickly.“ The climate test chambers WK3-180/40 used work with temperatures from - 40 to + 180 °C and a relative humidity of 15 to 98%. This means they cover all standard testing tasks at WACKER, which carries out testing on bitumen mainly in the range between - 20 and + 70 °C. In addition, there is a test chamber for large test specimens available at the site, as well as a frost-dew chamber. Single and multi-stage tests are carried out in the test chambers over periods of between one hour and four weeks and more. One typical test is the startup and holding of various temperatures in succession, for example 0 °C, + 23°C, - 5 °C and - 20 °C.

Tests at the inventor of dispersible powder

In the bitumen sector, WACKER mainly develops sealing coatings for cellars and roofs to customer orders. For this, the existing bitumen paste is optimised with VINNAPAS® dispersible powder and other additives in such a way that the required resistance in the respective area of application or climatic zone is reliably guaranteed. As the manufacturer of the first dispersible powder in 1957 and market leader in this field, WACKER has a comprehensive range of experience to fall back on. This is important since numerous customer-imposed and building approval-related requirements have to be observed during development. No fewer than 21 different standards must be taken into account for bitumen products for public buildings, for example. As a quality leader, WACKER feels it is especially important to observe the required test values exactly, as Killermann explains: “We always want to offer our customers the perfect solution. For this, we need precise test results of course, which we can reliably achieve using the testing technology from weisstechnik.”

Simple handling, perfect planning

Precise planning is necessary to exploit the testing technology of the laboratory group in Burghausen in the best way possible. There is an employee responsible, who coordinates all the tests and programs the testing systems in such a way that they are ready for use perfectly conditioned at the required time. Since the application engineers’ workstations are quite some way away from the test laboratory, they can monitor the tests via remote access at their PC or smartphone at any time – even at the weekend. This is extremely convenient, particularly when longer series of tests are performed.

Make the world a little better with testing technology

The development and optimisation of basic materials, recipes and finished mixtures in climate test chambers offers many advantages. On the one hand, WACKER can test and adapt viscosity and curing behaviour. This makes it possible for the company fulfil the requirements of its customers, who always demand shorter construction times with reduced drying times and work even at low temperatures. On the other hand, the testing technology makes a contribution to environmental protection. “Rather than flying around the world and testing a product in Moscow, Dubai and Hamburg, we produce the climate in the test chambers on our premises. That is faster, more reliable and goes easy on the environment,” concludes a satisfied Mr. Killermann.

Reprint free of charge. Please state Weiss Technik as the source.

Weiss Technik

With the slogan “Test it. Heat it. Cool it.”, the Weiss Technik companies offer solutions that can be used across the globe in the fields of research and development, as well in the production and quality assurance processes for numerous products. A strong sales and service organisation with 22 companies in 15 countries at 40 locations offers excellent support to customers and a high level of operating reliability for the systems. The weisstechnik® brand includes customised solutions for environmental simulations, clean rooms, air conditioning, air dehumidifying and containment solutions. With the test systems from the environmental simulation sector, environmental influences across the globe can be simulated in time lapse. The product to be tested is investigated under real loads in terms of its functionality, quality, reliability, material resistance and lifespan. The dimensions of the test equipment range from laboratory test chambers to test chambers for aeroplane components with a volume of several hundred cubic metres. The Weiss Technik companies are part of the Schunk Group, which is based in Heuchelheim near Gießen/Germany.

Schunk Group

The Schunk Group is a global technology corporation – acting as a medium-sized company but with a global business unit structure. The company is a leading provider of products made from high-tech materials – such as carbon, technical ceramics and sintered metal – as well as machines and plants – from environmental simulation to air-conditioning technology and ultrasonic welding to optical machines. The Schunk Group has over 8,500 employees across 29 countries and generated a turnover of 1.28 billion euros in 2018.