OAC-140SP

The OptoTech OAC-140SP is the most flexible coating machine in its size on the market. This evaporation coater is used for the application of high quality anti-reflective (AR) coatings, clean coats (CC), mirror coats as well as tinted coats on ophthalmic lenses. The OAC coating system is characterized by the product quality for which OptoTech is known, ease of use, and exceptional reliability in the daily production operation.

Solicitud de contacto

Aspectos destacados

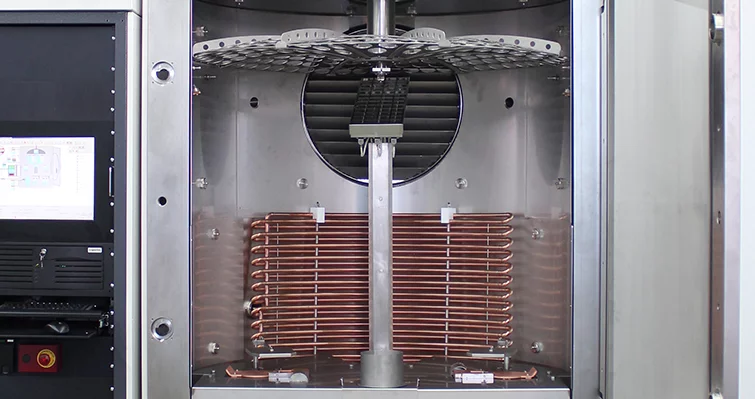

- High quality stainless steel vacuum chamber with electropolished surface

- Pumping system with diffusion pump

- Meissner-Trap with cryo-cooler

- Process control unit with user interface

- Electron-beam evaporation system

- Thermal evaporation source

- Ion source

- IR-heating system

- Thin film deposition control with quartz crystal method

Ventaja del sistema

- Perfect for large RX-labs

- Reliable in the daily production

- Easy-to-operate, highly flexible and with very short cycle times

Características del proceso

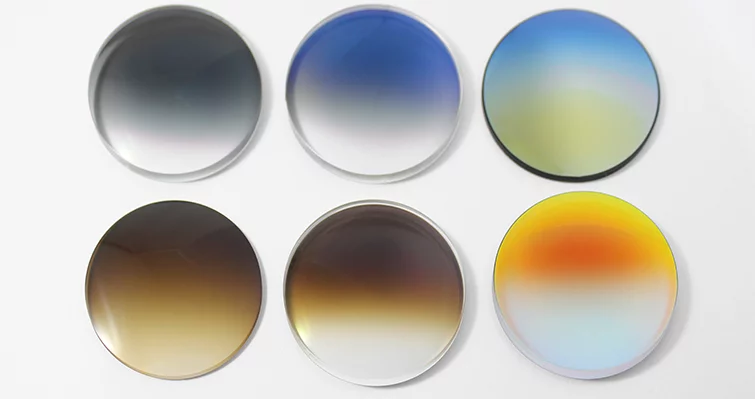

NEW Tinted Gradient AR process: The tinted gradient is applied directly in the AR-process in highest quality (100% stable tinting results) without the need of a separate tinting machine. You can now coat different indices (also high index) as well as freeform lenses in the same batch. Moreover, you have a maximum flexibility in the design of your gradient with regards to color, length, position and intensity. Even customized gradient shapes are possible. Moreover, Tinted Gradient AR can be combined with hydrophobic and AR-coatings in one and the same process as well as high fashion mirror coatings in a separate process.