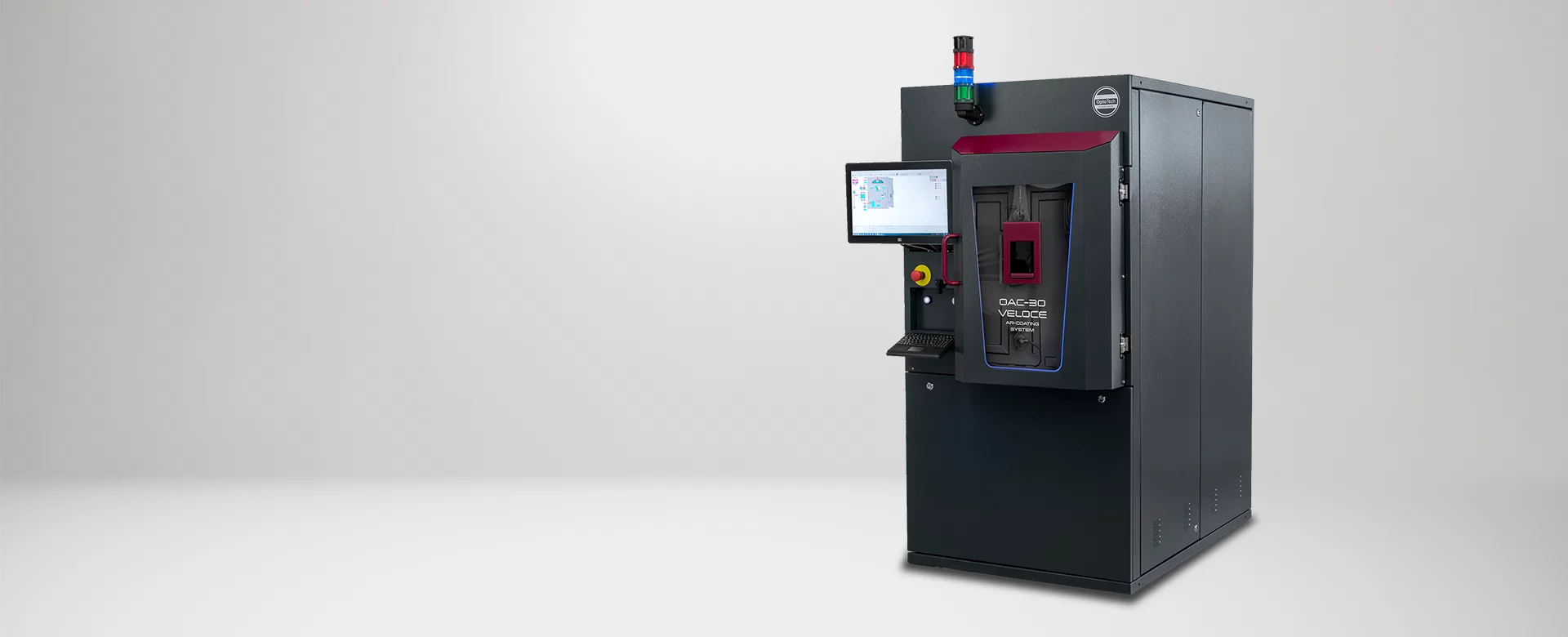

OAC-30 Veloce

Compact, powerful, and future-ready - our latest coating system OAC-30 Veloce delivers outstanding performance in the smallest footprint on the market. Designed for flexibility and reliability, it helps labs of any size achieve higher productivity, more consistent coating quality, and lower operating costs.

Revêtement

AR-Coating

Demande de contact

Points forts

- Optimized chamber design for shorter pump-down and cycle times that will accelerate your coating process and improve overall lab efficiency

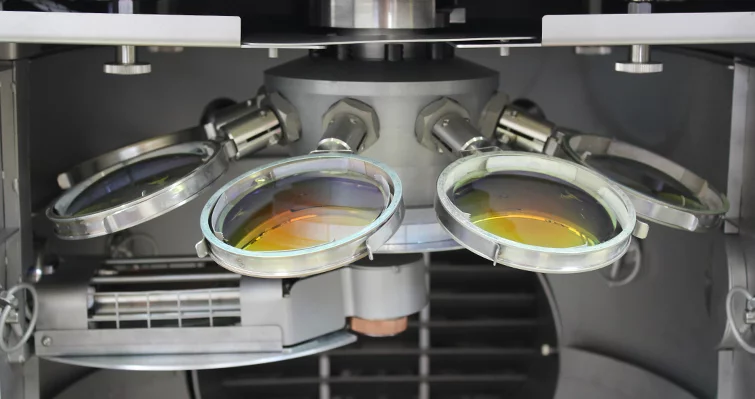

- Enhanced material and substrate handling thanks to integrated thermal evaporator to support hydrophobic and multi-material coatings, as well as the front-mounted adjustable heater that enables consistent heating for both plastic and mineral lenses

- Precise and stable coating process with repositioned crystal sensor and optimally positioned distribution mask ensuring accurate thickness control, uniform coatings, and high process stability

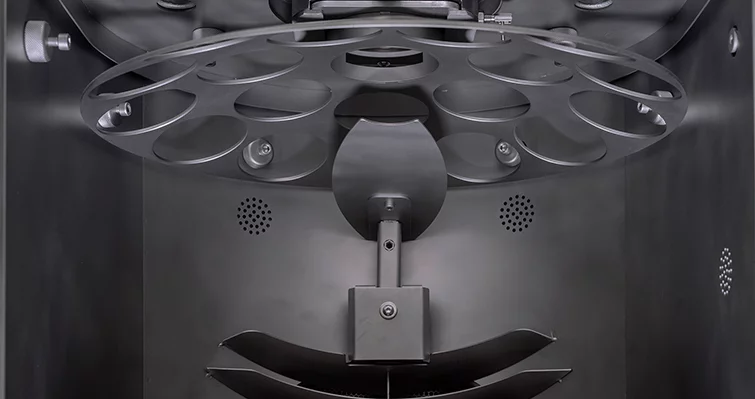

- Interchangeable dome and flip-over configurations for flexible lens diameters and production requirements

- High quality stainless steel vacuum chamber with electropolished surface

- Compatible with hard coats made by spin-coating or dip coating

- Pumping system with turbo pump and pre-pump

- Electron-beam evaporation system

- Ion source ideal for all lab sizes machines

- Thin film deposition control with quartz crystal method

- Intelligent vacuum pressure control for reliable, repeatable results

- Process control unit with user interface

- Industry 4.0/5.0 integration with digital monitoring and data tracking

- The redesigned layout ensures that all key components are easy to reach, making maintenance and servicing faster and more efficient

Avantage du système

- Smaller footprint, bigger performance - lightest and most compact platform on the market, easy to install in any lab

- Ideal entry system for AR coating - perfect for small Rx labs and labs starting with in-house AR production

- Reliable for daily use - built for consistent performance and stable results in continuous operation

- Fast and flexible - Easy-to-operate, highly flexible and with very short cycle times. Adaptable configurations keep your lab efficient and responsive

- Future-ready – full Industry 4.0/5.0 integration for smart process monitoring and data tracking

- Service-friendly – redesigned layout gives quick access to all key components for reduced downtime

Caractéristiques du processus

DURACOTE - AR coating on plastic lenses

DURAFLEX - Mirror coating in different vibrant colours

DURAQUARTZ - AR coating on mineral lenses

IRIDIO - Anti-static coating

IR PROTECT - IR protection with NIR blocker

RELAX - Blue light protection filter

UV - UV light protection filter

Options

- Meissner-trap with Polycold cooling system for shorter process cycles

- Gate valve for turbo pump

- Dual position thermal evaporator: Handle two thermal sources for even broader process possibilities

- Dome sectors or Flip-Over insert

- Wide range of coating consumables and coating materials available