Mobile version with base frame

Base frame to convert a table top unit into a mobile standalone unit with a table top working level. It comes with four castors, two of which equipped with arresting device.

The solution for temperature tests with limited space. The test chambers in the LabEvent range are available with test chamber volumes from 16 to 210 liters. With a wide temperature range, they are ideal for reproducible tests on small test samples in the fields of research, development and quality control. LabEvent chambers comply with common test standards such as DIN, ISO, MIL, IEC, DEF, ASTM.

Contact request

Minimal external footprint for your testing requirements, in some cases less than 1 m². In addition, the cabinets can be stacked on top of each other using a specially designed device.

Our single-stage systems (down to -40°C) are equipped with CO2 refrigeration technology (GWP = 1). Even at -40°C, the system still offers sufficient power to operate your test material.

Significantly more energy-efficient than comparable appliances on the market.

Plug&Play thanks to 230-volt connection.

The very low noise level makes it possible to work in close proximity to the cabinet. An additional option allows to reduce the sound pressure level even more.

Triple test material fuse included as standard. Active test items can be deenergized via a potential-free contact. Test chamber can switch off in the event of a fault in the test material or be set to a defined value (optional).

The LabEvent is also available for Environmental stress screening tests, up to 5 or 10K/min temperature change rate.

Every test item and test is different. A huge range of accessories available so the customer really gets the chamber they want to suit their application and are not buying any redundancy.

In the basic equipment, a USB port for data recording (csv) and an Ethernet port are available. The cabinet can be controlled via the network connection with our software S!MPATI® or the data can be recorded. Additionally, the cabinet can also be controlled by external programs via our own protocol SimServ.

Independently adjustable temperature limiter tmin/tmax, separate sensor installed in the test chamber. Dehumidifier to prevent condensation formation on the sample. Software temperature limiter tmin/tmax, individually adjustable fixed value. Potential-free contact specifically for heat-emitting test specimen, connected to socket max. load 24V 0,5A.<br />

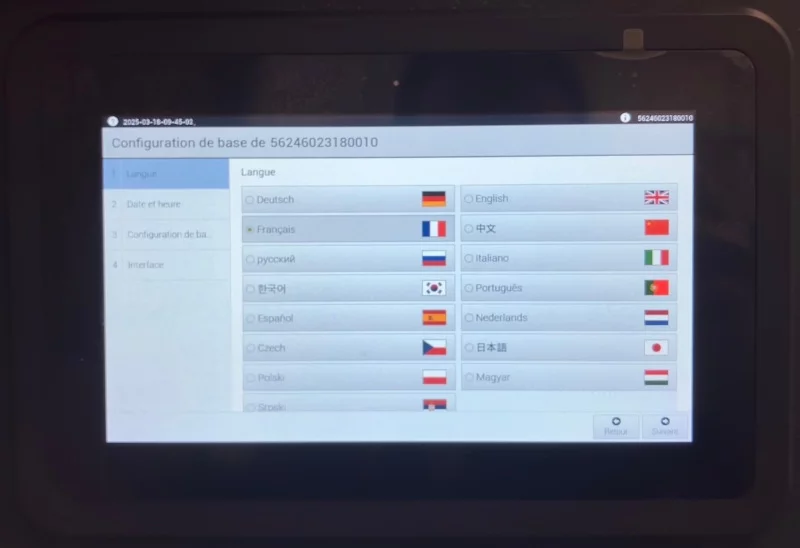

Operation/programming and monitoring unit with 18 cm (7"). With this, all settings can be made and test programs can be conveniently programmed.

Illuminated test chamber made of corrosion-resistant stainless steel 1.4301. Thanks to special welding and smooth surfaces, the test chamber is easy to clean.

Door adapted for one-hand operation, lockable, hinged on the left side. <br />

The size, position, and design of our access ports are as individual as your test object and your tests. Talk to us. We have the right solution for every requirement.

Two block and steering rollers provide sufficient mobility in the mobile version.

Our single-stage systems (down to -40°C) are equipped with the innovative CO2 refrigeration technology (GWP <1).

Find out more!

Changes to the installation site only arise when using an RCD residual current device (FI circuit breaker). Please note that connection to an RCD residual current device < 300 mA is not possible.

The 16, 34, 64, 100 and 150 liters variants are designed as bench top units as standard, but can also be configured optionally as mobile units for easy transport. As bench-top sized, 2 devices can be placed on top of each other with our optional stacking frame. The 110 and 210 liters variants of the LabEvent are developed as mobile versions in their standard configuration.

The LabEvent portfolio offers a broad range of configurations to address a large variety of customer needs. For example, the machinery of most 34, 64, 100 and 150 liters variants is placed on top of the chamber. This allows to include an access port in the floor. On the contrary, the machinery of the 110 and 210 liters variants is placed on bottom part of the chamber. This allows to include an access port in the ceiling. For stress screening tests, the 100 and 150 liters variants are available in a -70°C - 10K/min version and the 110 and 210 liters variants are available in a -70°C - 5K/min version.

| ||||

|---|---|---|---|---|

| Testspace volume (l) | 16 | |||

| External Dimensions (HxWxD) [mm] | 625 x 470 x 570 | |||

| Test Space Dimensions (H x W x D) (mm) | 205 x 310 x 310 | |||

| Temperature range [°C] | -30 … 130 | |||

| Temperature Change rate, cooling (air-cooled) (K/min) | 6 | |||

| Temperature Change rate, heating (air-cooled) (K/min) | 5 | |||

| Sound Pressure Level (dB(A)) | 52 | |||