We set the bar high when it comes to service.

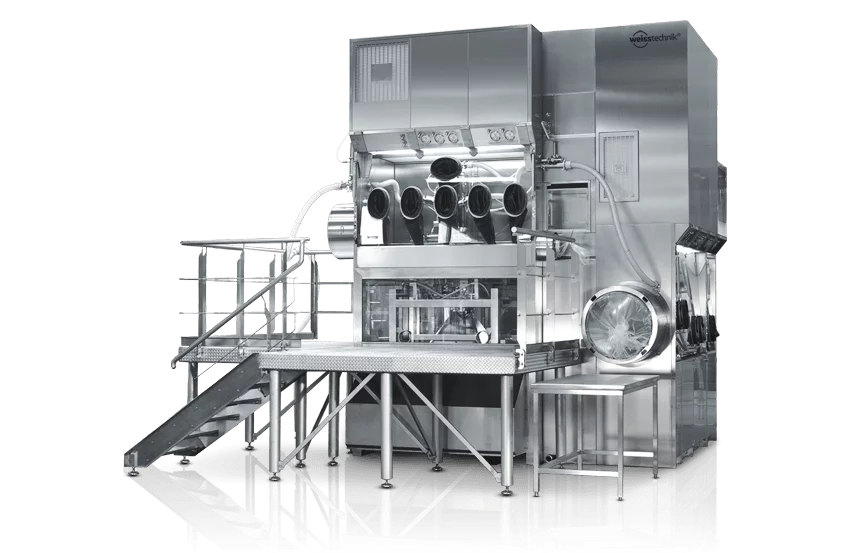

Find out more!WIBObarrier® Clean Air Curtain For The Pharmaceutical Industry

Weiss Technik’s WIBObarrier® system was designed especially for working areas in which it is necessary to protect persons in a stable manner and maintain a high clean air quality. Our innovative laboratory safety workstations operate in accordance with the three-zone principle. The outlet nozzle integrated in the anterior hood region forms a stable clean air curtain, which protects employees, products and ambient surroundings.

Much like a magnet, the barrier curtain attracts particles which are created in the product area, and guides these directly to the intakes. Even particles that enter the working area due to employee interference are captured by the clean air curtain and guided straight to the front suctioning device, ensuring the product is free of contamination. Whilst the product is streamed with HEPA-filtered clean air, the HEPA-filtered barrier curtain also offers protection against turbulence caused by the employee’s movements.

When designing all WIBObarrier® equipment, Weiss Pharmatechnik placed emphasis on adherence to product exposure limits in accordance with OEL-levels and clean air qualitites in accordance with DIN EN ISO 14644-1. The WIBObarrier® clean air system is available in closed form (CCS – Closed Containment System) and in open form (OCS – Open Containment System).

Optimal protection of products and operators thanks to:

- 3 zone principle

- Stable clean air curtain

- Extraction of airborne particles

- Protection against turbulence

- Cleanliness class 5 as per DIN EN ISO 14644-1