Customer-oriented

Detailed needs analysis and comprehensive advice.

Hydrogen produced in a climate-neutral way is a central key to the energy turnaround. It can substitute fossil fuels and help to sustainably reduce CO2 emissions. Numerous innovative hydrogen and fuel cell applications are therefore being developed at present in a highly dynamic market. However, these must not only make ecological sense, but also be particularly safe for the user. As an experienced testing technology specialist, we have developed a unique, multifunctional and modular H2 safety concept together with TÜV-Rheinland Industrieservice GmbH.

H2 and Fuel Cell Testing

Hydrogen is flammable and highly explosive. In order to optimally protect members of staff, test equipment and the test specimen, test facilities for H2 applications must therefore be designed to be particularly safe. Since there are still no generally applicable specifications for the planning and design of the systems, we have developed our own safety kit together with TÜV-Rheinland Industrieservice GmbH. This enables turnkey solutions for tests with hydrogen and is divided into three levels.

H2 Mobility Testing

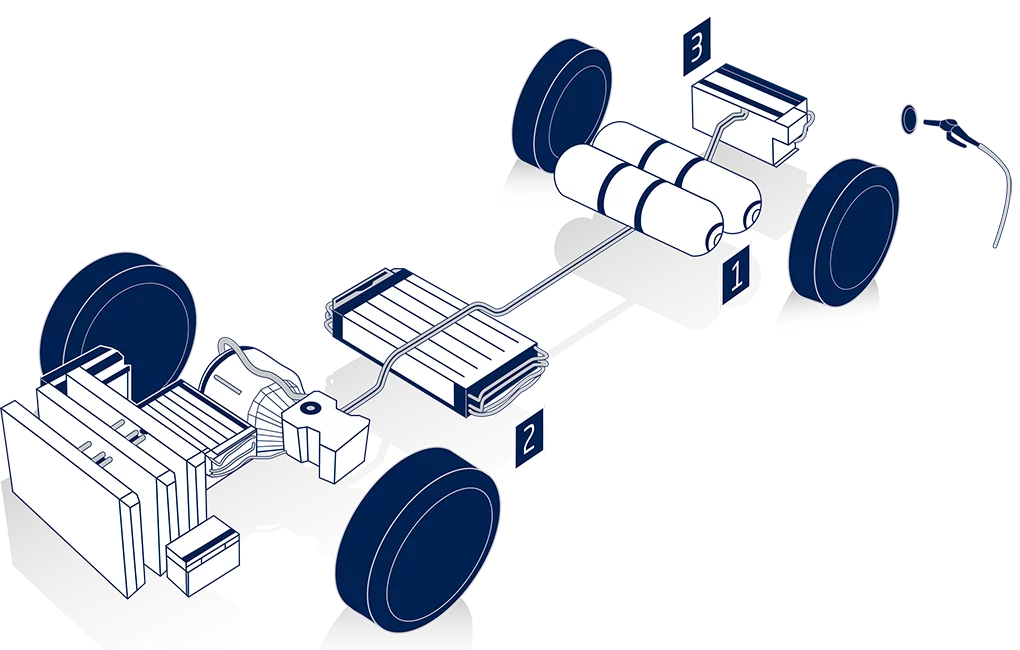

Heat, cold, humidity, wind and dust: Hydrogen-powered vehicles and their components have to pass the same environmental simulation tests as vehicles with combustion engines or electric drives. However, they require significantly higher testing equipment safety standards. The reason is, on the one hand, the high flammability and high explosiveness of hydrogen, which pose a danger to members of staff, the test specimen and the test facility. On the other hand, in the case of vehicles with hydrogen-powered fuel cells, three different sources of danger must be considered, both individually and in combination.

| 1. H2 tank | |

| The tank stores gaseous hydrogen under high pressure | |

| Danger | Uncontrolled H2 release |

| Ignition of an explosive H2 atmosphere | |

| 2. Fuel cell stack | |

| Conversion of the energy stored in the hydrogen into electrical energy | |

| Danger |

Uncontrolled H2 release |

| Ignition of an explosive H2 atmosphere | |

| 3. Lithium-ion battery | |

| Buffer storage for the generated electrical energy | |

| Danger | Thermal runaway with uncontrollable consequences |

| H2 release and ignition of an explosive H2 atmosphere | |

The complex hazards that arise during tests of fuel cell-powered vehicles, but also with direct combustion engines, require a safety concept that is optimally adapted to them. This includes organisational measures, measures to avoid hazards, and measures to remedy hazardous situations that have arisen. Weisstechnik offers you the appropriate combination of suitable measures, based on the standardised risk assessment and customer-specific specifications.

Prevention ot the emergence of hazards

Technical solutions that detect and prevent the emergence of hazards at an early stage.

Elimination of existing hazards

Measures to limit the hydrogen input so that critical situations that arise do not lead to fire or explosion.

Operator obligations

Specifications and guidelines for the safe planning and execution of tests with fuel cells.