Complete solutions for test systems from a single source

Turnkey test facilities for a wide range of applications

As an experienced system partner for turnkey test system construction, weisstechnik® serves a large market. Its range extends from roller test stands to altitude simulation chambers and covers almost all climatic conditions and load conditions for fuel cells, whole vehicles, and other test specimens worldwide.

Our facilities and examples

Simulate our facilities, individually or in combination:

- Temperature

- Moisture

- Vibration

- Precipitation

- Salty atmosphere

- Controlled atmosphere

- Pressure

- Radiation

- Wind

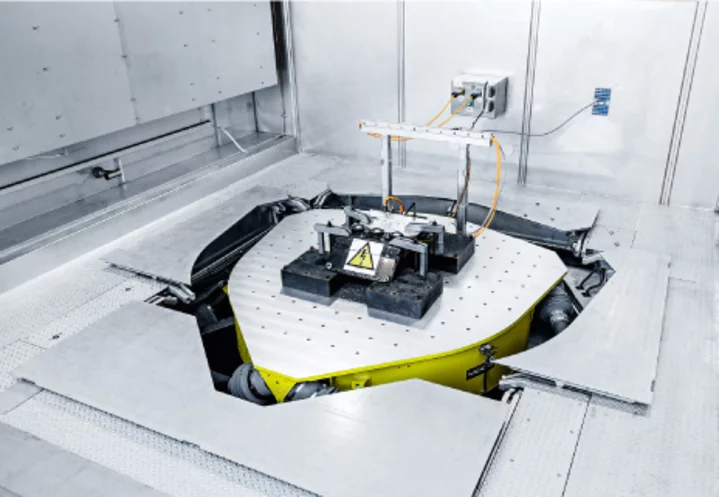

Examples of test chambers with/without integrated test benches:

- Shaker

- Hydropulser

- MAST Table

- Sun simulation 4-posters

- NVH

- VOC

Our turnkey services and solutions

Our turnkey services

- Initial consultation

-

Development of rough idea and budget price

-

Planning and quote based on specifications

-

Implementation as general contractor

-

Development and delivery of test equipment

-

All trades and suppliers

-

Calibration and commissioning

Our test solutions

- Stability tests

- Performance tests

- Degradation tests

- for fuel cells and complete vehicles

Budget, timing and technology firmly under control

When planning and implementing test benches and other test facilities, it is important to keep a firm eye on the technical requirements, timing, and budget at all times. As a general contractor, we offer our customers a number of clear advantages.

Our strengths:

- Implementation in line with the budget

- Highest cost transparency

- Timely coordination

- All suppliers and trades

Test technology proven worldwide

Experience, commitment, success

The successful planning, smooth realization, and punctual commissioning of a test facility is teamwork. That’s why we use the experience of our specialists and train all employees consistently and comprehensively.

Our team:

- Experienced planners, project managers, and engineers

- Personal commitment and high flexibility

- Competent answers and industry-proof solutions

- Confident cooperation with all trades

Flexible technology, powerful performance

We are an experienced partner for individually planned test solutions and customized test facilities. In doing so, we work from the initial idea to far beyond the last screw and adapt our services precisely to the respective requirements.

Your benefits:

- Customized test solutions

- Customer-oriented processes

- Service packages tailored to your needs

- Reproducible test results

Worldwide competent service

Our service team covers the whole of Germany and comprises 500 employees worldwide. With our service specialists, we ensure that test facilities function reliably and that any necessary maintenance and repairs are carried out as quickly as possible.

Convincing service:

- Personal contact

- Worldwide service network

- Highly qualified service specialists

- Reliable spare parts supply

- Maintenance, servicing, and repair

- Qualification, factory calibration, and calibration

- Conversion, modification, and modernization

- Training programs for customers