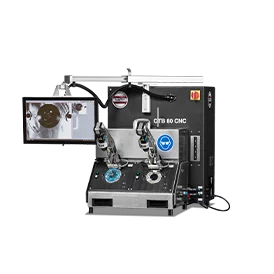

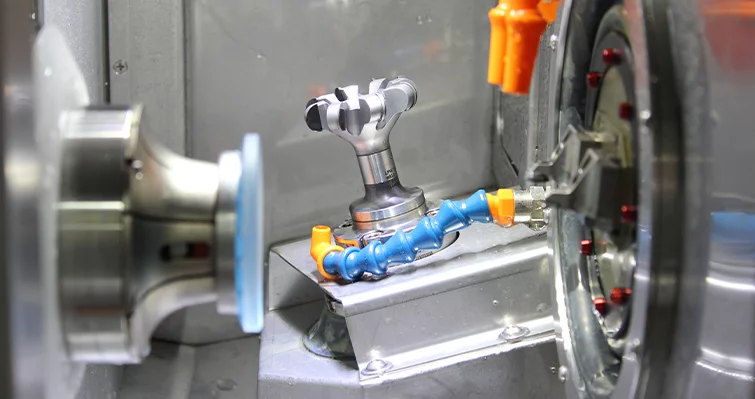

FLASH Store

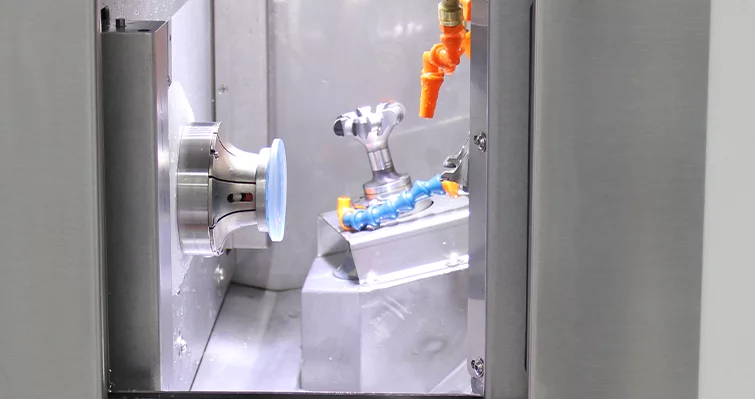

The low cost digital surfacing machine FLASH Store is especially designed to offer even small and smallest LAB‘s an entrance in freeform technology. For the production of freeform surfaces for ophthalmic lenses including edging (elliptical and chamfer) for progressive spherical, toric and atoric lenses with prismatic, concave or convex surfaces made of plastic (CR 39, Polycarbonate, Trivex).

Spectacle optics

Generating

Manual

Plastic

Close

Video

Contact request

Highlights

- The low cost digital surfacing turning machine FLASH store is especially designed to offer even small and smallest LAB's an entrance in freeform technology

- The simple but high-quality design of the machine allows the production of all plastic materials and designs on the market

- For processing backsideprogressive, atoric, individual, front progressive and standard toric surfaces

- Machine base made of rigid grey cast

- Fast-Tool highspeed linear drive

Process characteristics

- Cut to smooth: approx. 50 surfaces / hour

- Cut to polish: approx. 25-40 surfaces / hour (Spherical / torical or A-torical)

- Cut to polish: approx. 20-35 surfaces / hour (Freeform)

Options

- Coolant tank

- Barcode hand scanner

- Remote diagnosis

- LAN connection