It is usually a long way from the idea to the finished dry room plan. Even minor changes to the dew point or the number of people in the room can lead to time-consuming rescheduling and have a considerable effect on the budget. With the new online configurator for dry rooms, Weiss Technik has shortened and improved this planning process. The configurator is a practical support for on-site consultation and allows an initial dry room layout to be created in real time.

Dry rooms for battery cell production

Regardless of whether they are classic lithium-ion or solid-state batteries, battery cells require an extremely dry climate in research and production because the active materials react strongly with humidity. In order to protect people, processes, products, and the plant, all work on batteries is carried out in dry rooms. However, as the performance of batteries increases, so does their energy potential. This further increases the importance of dryness. Planning dry rooms used to be quite time-consuming. In order to find an optimal balance between technical requirements and the budget, lengthy correction and adjustment loops were usually necessary.

Simulating factors and effects

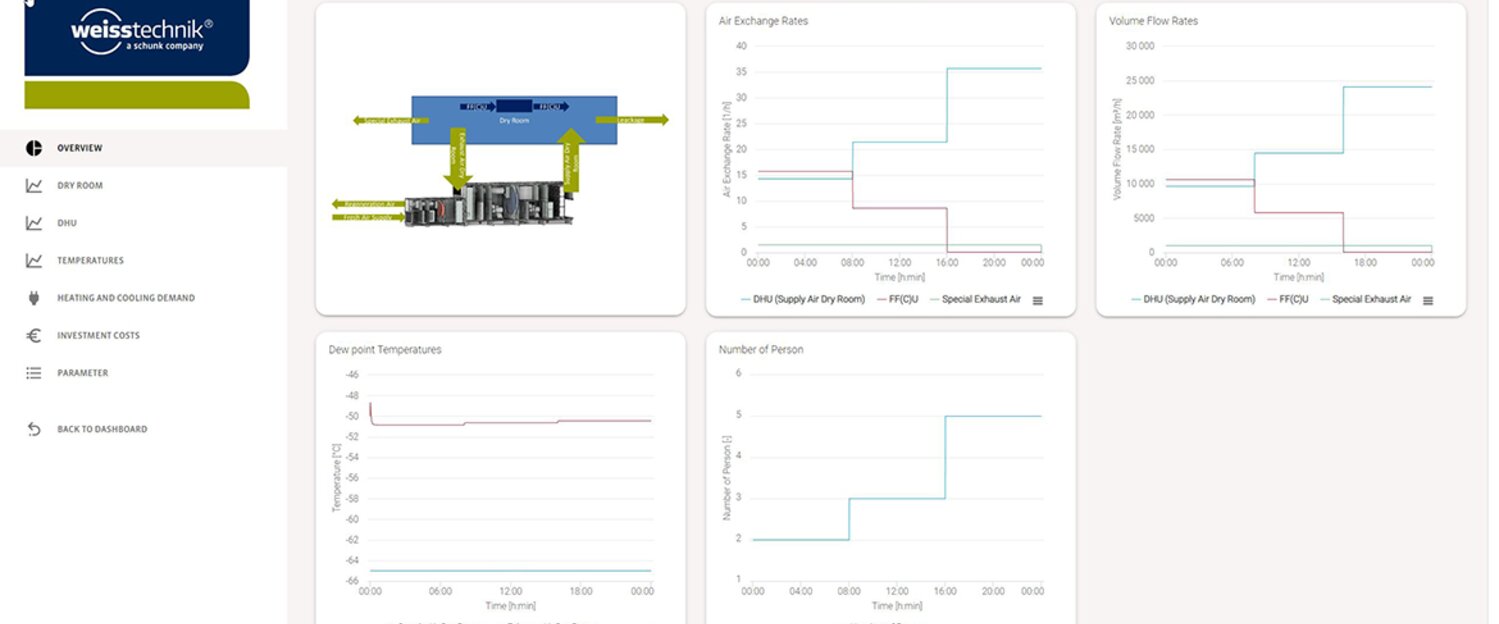

With the new online configurator, an initial concept for a dry room can be created quickly and easily and further optimised with the client using a computer. This speeds up planning and ensures greater transparency. Changes to individual factors and parameters can be simulated directly, and effects on the design of the dry room are displayed immediately. The possibility of directly comparing different layouts is particularly useful. Only after the rough planning has been completed and the initial budget has been determined does the detailed planning begin in the design department.

Energy factor: dehumidification

Air dehumidification is an energy-intensive process. Up to 60% of the energy required for battery production is used just for this. This accounts for a considerable proportion of the costs of a battery. For an efficient solution, it is therefore particularly important to optimally coordinate all parameters when planning a dry room. The three most common factors that disrupt efficiency and dehumidification are leaks, air extraction in production, and the presence of others in the dry room. Using the online configurator, the various possibilities can be easily simulated and customised.

Adjust parameters

The simulation tool systematically goes through all relevant parameters. The planning process starts with the floor plan of the dry room. The desired dimensions are set using a slider, and selection options such as suspended ceilings can be added at the touch of a button. The wall construction, leakage rates, and dew point must then be selected. Ambient conditions such as temperature, humidity, and air pressure can also be set as well as the waste heat from machines and desired air exchange rates.

Calculate the human disturbance factor

Because just one person releases around 120 g of water into the environment per hour, the number of people working in the dry room has a considerable influence on air dehumidification. An additional person means major changes in the technical requirements and subsequently also in the costs. The online configurator therefore allows alternative scenarios. For example, operation with different numbers of people can be simulated, and the effects on technology and costs can be directly considered.

Consideration of air extraction and air purity

Another possible problem factor the waste gases produced during the welding of battery cells. These gases must be discharged quickly and safely. The required exhaust air volume considerably increases the demand for fresh air to be dried. With the online configurator, specific values can also be entered for this, and various scenarios can be simulated. This also applies to possible requirements for air purity. Here, the ISO 7, 8 or 9 cleanliness classes commonly used in battery production can be planned at the touch of a button. This is important in order to protect the layers of the batteries (which are becoming increasingly thinner because of the increasing power density) from dust and contamination.

In focus: optimal design according to demand

Once all parameters have been determined, the online configurator calculates the layout of the dry room and dehumidification technology. The latter usually works in two stages. In the pre-drying stage, adsorption dryers reduce the moisture content of the fresh air from the environment; in the second stage, the air is dried to the target value. The Active Leakage Management (ALM) developed by Weiss Technik is automatically taken into account. This greatly reduces leakage rates through various measures, including the intelligent adjustment of the air exchange rate and the use of textile hoses for air injection. Other measures include using mainly internal air ducts, fewer ducts, and welded return air ducts. After the dry room has been designed and optimised, an initial budget can be drawn up. After approval, the detailed planning of the dry room can begin.

Accelerated ordering process

Julian Kalmus, project manager at Weiss Technik and co-developer of the online configurator, is enthusiastic about the possibilities. “The aim is not to make a finished order directly via the configurator – dry rooms are far too complex for that. But the configurator can considerably speed up the ordering process and makes planning transparent”. In the configurator, clients can immediately see how seemingly small changes can affect the overall configuration and what alternatives are possible. “This makes it a real sales booster that helps to achieve better results faster and more reliably”, says Kalmus.

915 words. Reprint free of charge. Please cite Weiss Technik GmbH as the source.