New vehicles release a wide variety of volatile organic compounds (VOCs) into the interior. These can be harmful to the health of vehicle occupants. To identify the types and concentrations of VOCs emitted inside vehicles, the Fraunhofer Institute commissioned the development of a drive-in test chamber for complete cars. The chamber allows for 46-hour tests under intense solar irradiation and precisely controlled climate conditions. Alongside the overall concept, Weiss Technik was specifically responsible for the chamber construction, air conditioning technology, and solar radiation.

Test solution for new automotive standard

VOCs such as benzene, toluene and styrene are released in vehicle interiors primarily from plastic components and adhesives. To obtain reliable information about the type and quantity of VOCs emitted, emission tests are carried out on vehicles in accordance with DIN ISO 12219-1. The Fraunhofer Institute for Wood Research investigates how VOC emissions affect air quality and carries out related testing. To enable the future testing of complete vehicle interiors of various sizes, rather than just individual components, the institute commissioned the design and implementation of a new test chamber. This presented a climate engineering challenge, as the airflow, climate control, materials used and solar simulation emitters must not affect the VOC measurements.

46-hour test with high temperature stability

According to the DIN ISO 12219-1 standard, VOC measurements of vehicle cabin air are carried out over a 46-hour multi-stage test cycle with distinct phases. Initially, the test chamber and vehicle are conditioned for 24 hours to meet the required standard conditions: 23–25 °C and 50 % relative humidity (±10 %). Following a 16-hour rest period, a baseline VOC measurement is taken inside the vehicle cabin. The vehicle is then heated in park mode for 4.5 hours with simulated solar radiation of up to 6,000 watts, and a second VOC sample is taken. The vehicle is then started and a third air sample is taken after 30 minutes with the engine running and the air conditioning or ventilation switched on. The samples are collected via special test tubes at the driver's head height and then analysed in a gas chromatograph. This allows us to determine exactly which VOCs are present in the vehicle interior and in what concentrations.

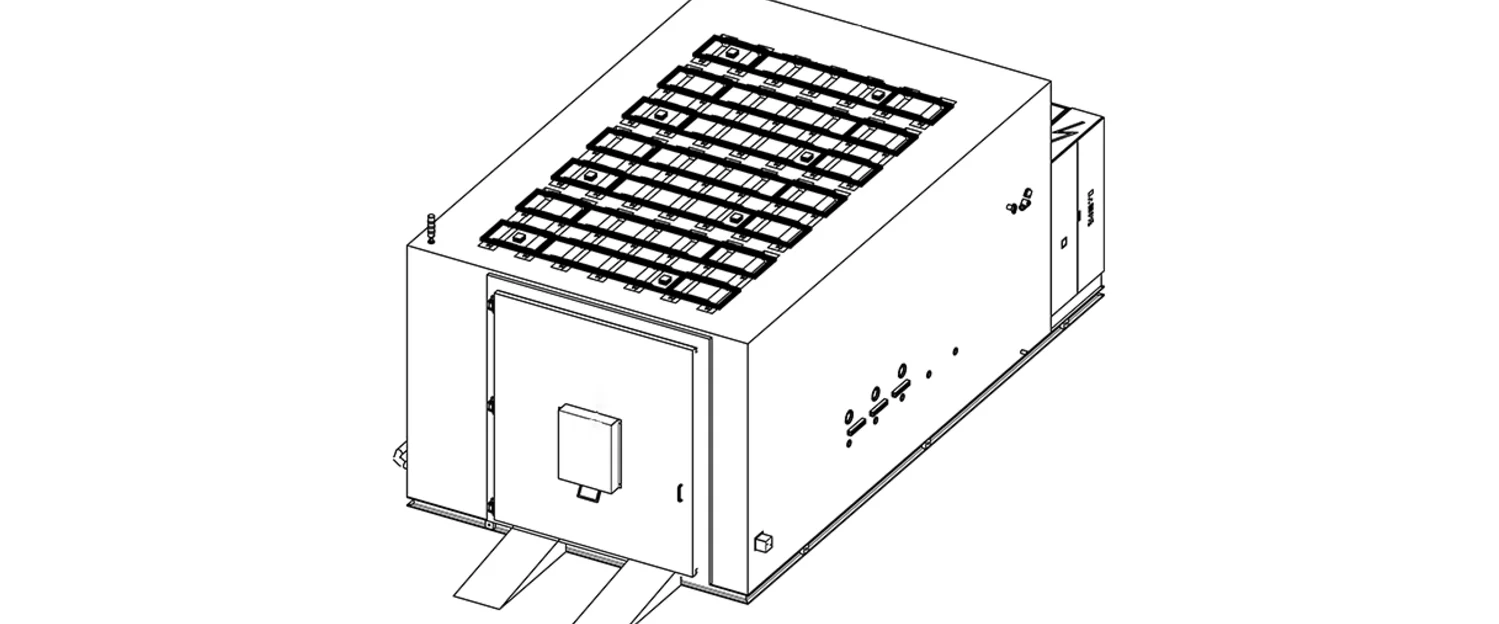

Climate chamber designed to have no impact on measurement quality

The EmissionEvent test chamber developed by Weiss Technik is 3,500 mm high, 4,750 mm wide and 8,350 mm deep. The test chamber has a net volume of 67 m3. During the planning stage, the aim was to eliminate as many potential influencing factors as possible. To achieve this, the chamber was built from ultra-smooth R2-grade stainless steel reflective sheet metal, to reduce potential VOC adsorption on its surfaces. The use of plastic, silicone and copper components was also avoided, as these would also distort the measurement results.

Challenges for air conditioning technology

Maintaining standard-compliant climate conditions in the chamber while irradiating the vehicle poses several climate engineering challenges. Firstly, extremely high temperature stability must be ensured throughout the entire test cycle, with a maximum deviation of ± 0.1 to ± 0.5 Kelvin. Secondly, the temperature level, air volume and air velocity must be coordinated in such a way that no air turbulence occurs and no condensate forms in which the VOCs can dissolve. The air flow was designed to be horizontal to ensure a particularly even air flow. The air flows slowly and evenly from left to right through the test chamber via perforated plates with holes of varying sizes in the chamber walls.

Infrared radiation system for natural solar heat

The park mode of the test standard requires a simulation of solar radiation. This focuses on sun-like heat input and the heating of the vehicle. UV radiation simulation is not required. For this reason, the use of special infrared emitters was the obvious choice. These are mounted on the test chamber ceiling and separated by a pane of special glass to prevent the measurement results from being influenced by outgassing from the emitters. The infrared emitters ensure highly homogeneous irradiation of the vehicle with excellent controllability of the radiation intensity. Depending on the size of the vehicle being tested, emitters can be switched on and off and the irradiated area above them can be easily adjusted.

Quick commissioning on site

Before delivery at the end of the year, the EmissionEvent test chamber will be fully assembled, tested and commissioned at the Weiss Technik factory in Lindenstruth. This will ensure that the system functions flawlessly and speed up assembly and commissioning on site. Frank Becker, the project manager at Weiss Technik, is very satisfied with the project's progress so far: “We were able to make full use of our comprehensive expertise in multiple areas of testing technology. The result is the world's first VOC test facility for complete passenger cars.” A similar test standard for VOC testing on lorries and buses is also expected shortly. With its experience with the EmissionEvent test chamber for passenger cars, Weiss Technik is already in the starting blocks.

Customised design for complete vehicles

Weiss Technik is an experienced system partner for testing technology in the automotive sector. The company offers standard solutions for a wide range of test specimens, test scenarios and testing standards. It also provides customised, special-purpose solutions tailored to customers' needs. This also include smaller VOC test chambers for vehicle components such as car seats and steering wheels. Weiss Technik also applied this expertise in the design of the test chamber for complete vehicles. Weiss Technik designs, develops, and delivers the complete test chamber – including climate control with temperature and humidity regulation, integrated solar simulation, the exhaust system for tests with running engines, as well as the overall system control.