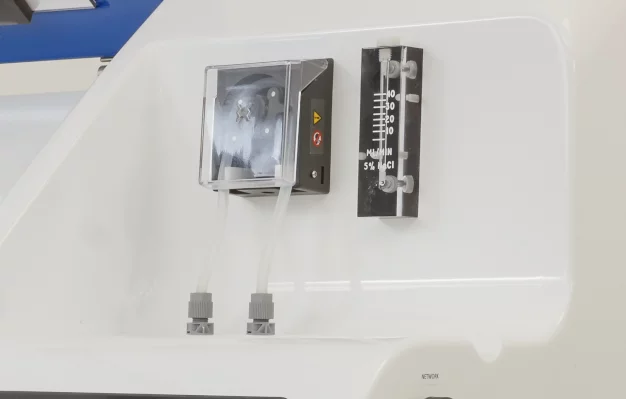

Liquid Immersion (ACC34)

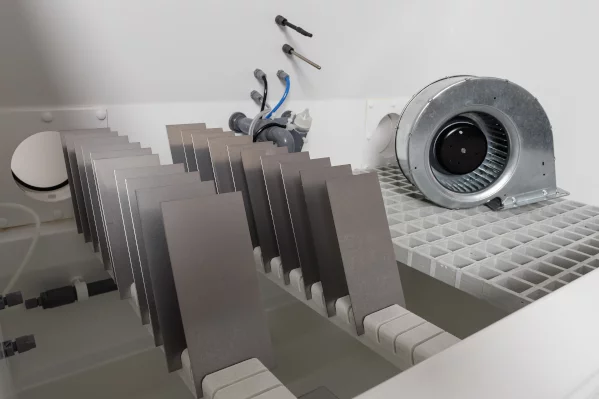

Under programmed control, heated immersion liquid (usually salt water heated to a user adjustable temperature up to +50°C/+122°F) is automatically pumped from the holding tank into the chamber, immersing the test samples. The liquid is automatically returned to the holding tank at the end of the immersion period. Immersion is a requirement of standards Hyundai CCT-C, CCT-D, Honda 5100Z & ASTM G44.