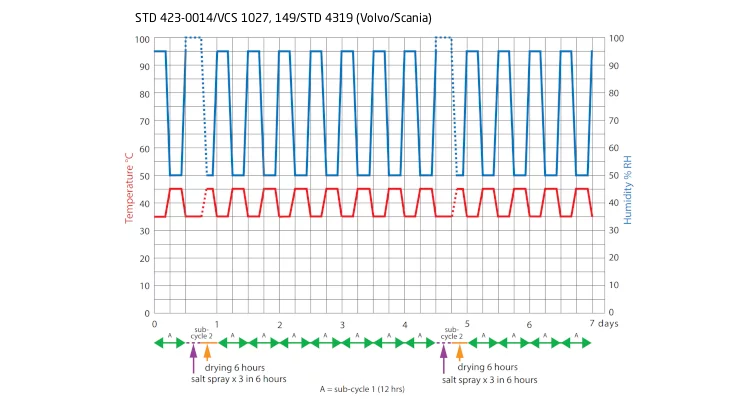

Wall Wash System (ACC42)

This option comprises of a water spray system to automatically wash the walls with water for a user adjustable number of minutes, at programmable points

within a corrosion test cycle. This is required for some automotive standards such as Renault D17 2028 or RNES-G-005 or ECC-1. It is also used when rapid cooling is required for JASO M 609, CCT-1, IEC 60068-2-52 and many other test standards.