DeBoxer

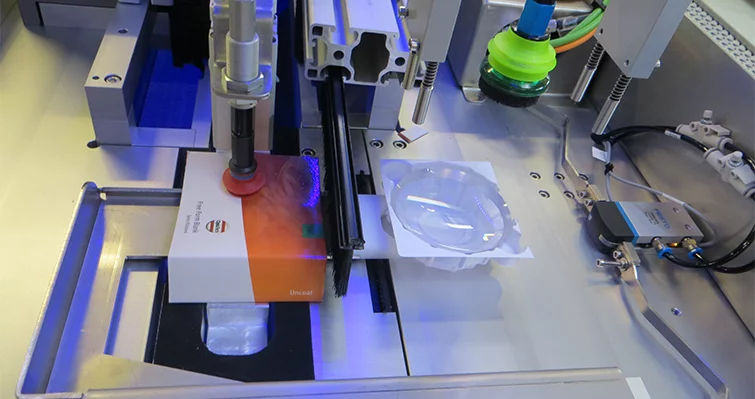

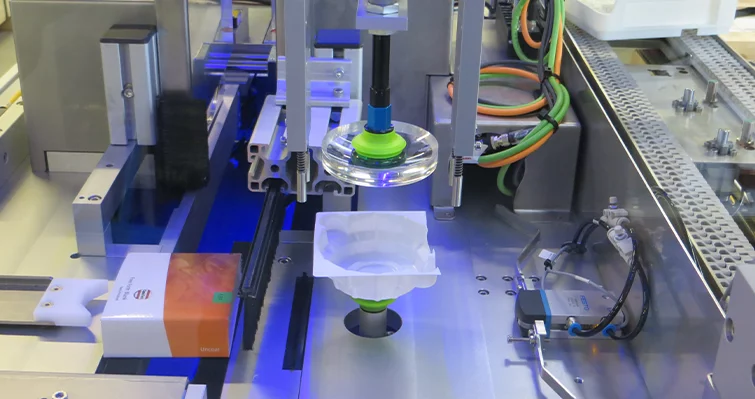

The new automatic DeBoxer is the first ever fully automatic system to specifically unpack semi-finished lenses. Depending on the type of boxes, this machine can unpack up to 300 lenses/h. Moreover, the DeBoxer can optionally be equipped with 2 outgoing conveyors for direct waste separation in carton and plastic.

Spectacle optics

DeBoxing

Automation

Plastic

Close

Video

Contact request

Highlights

- Especially developed to unpack semi-finished lenses

- Depending on the type of boxes, this machine is able to unpack up to 300 lenses/h

- Suitable blank boxes: from 70x70x15mm to 95x95x35mm with automatic in-process measuring

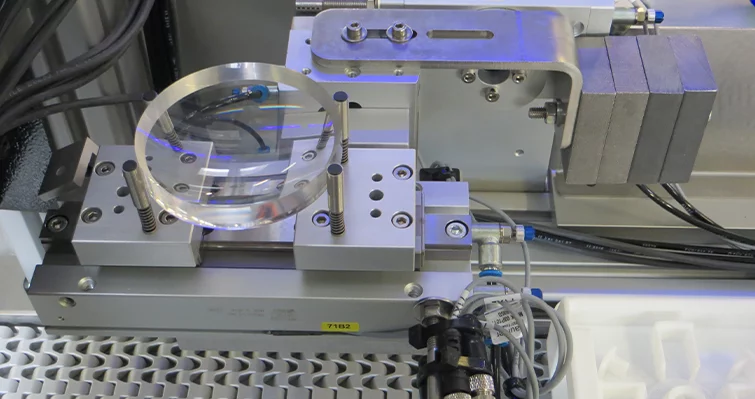

- Never touched front curve while processing

- Sustainable green process: Separation of plastic and carton into separate waste containers

- Open System: Can be used in combination with other OptoTech and Non-OptoTech machines

- Job-tray detection with RFID and Barcode-Scanner

- New brushless EC flat Motor and Servo Motor controlled cutting unit

- New generation of low air vacuum consumption

- Completely covered. Safety-unit with double doors.

System advantage

- Fast: Unpacking of up to 300 lenses/hour

- Clean: Automatic waste & recycling management to separate plastic and carton into different waste containers

- Reliable: No contact with front curve during handling process to ensure minimal risk of surface damage

- Economic: Fully automatic process using the latest low air vacuum technology

- Easy access to all parts of the machine

Options

- Waste conveyor belts for direct waste separation in carton and plastic material

- Knife sharpening device