Lens Washer

The Lens Washer is a fully automated system for cleaning ophthalmic lenses and sun protection lenses made of plastic and mineral glass, as well as casting molds made of mineral glass. It removes any adhesive, polishing or dirt residues and fingerprints on the surface lens.

Spectacle optics

Cleaning

Automation

Plastic

Mineral Glass

Molds

Close

Video

Contact request

Highlights

- Modular System: Number of chambers can be defined individually according to customer requirements

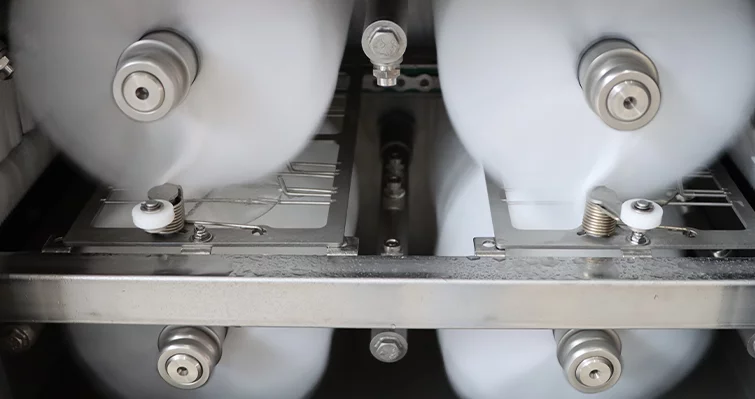

- Brush station with 4 rotating brushes with adjustable rpm driven by servomotors

- Regulated water flow and temperatures up to 90° C depending on process

- Fully equipped water tanks with integrated heating elements and sensor system for consistent temperature management

- Job Identification: Job can be identified in every stage

- Special Air Control System for unreached dry lenses

- Optimized energy concept: double-walled casing with insulation material for significant heat and energy conservation

- Inline System: With smooth handling for automatic loading and unloading

System advantage

- Multi-stage cleaning process for spotless lens surface. Perfect preparation for the inspection process (surface ready for inspection).

- Optimized energy concept

- Best accessibility for service and maintenance

Process characteristics

Multi-stage cleaning process for spotless lens surface:

1. The first brush chamber operates with a process-optimizing cleaning agent to dissolve any hard residues

2. The second stage consists of brush and rinsing chambers incl. transfer chambers that use DI-water to remove any substances on the lenses

3. In the last stage the lenses are dried in a drying chamber with a unique air jet and filter system for precise air control