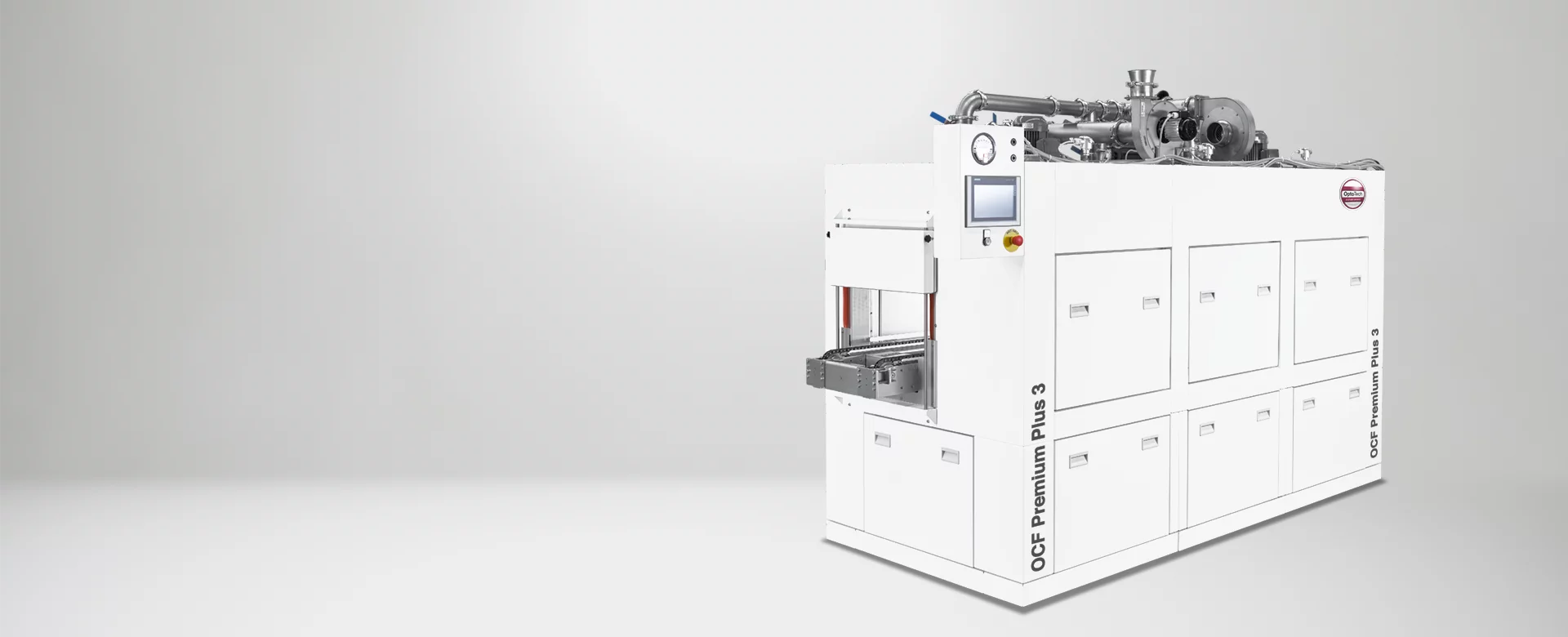

OCF Premium Plus 3

The OCF Premium Plus 3 is especially designed for curing coatings on ophthalmic lenses in a continuous cleanroom conveyor furnace after the hardcoating process. The modular system has 3 individually controlled heating zones whose working temperature can be set independently of each other offering maximum process flexibility.

Coating

Curing

Contact request

Highlights

- The OCF Premium Plus 3 is especially designed for curing coatings on ophthalmic lenses in a continuous cleanroom conveyor furnace after the hardcoating process.

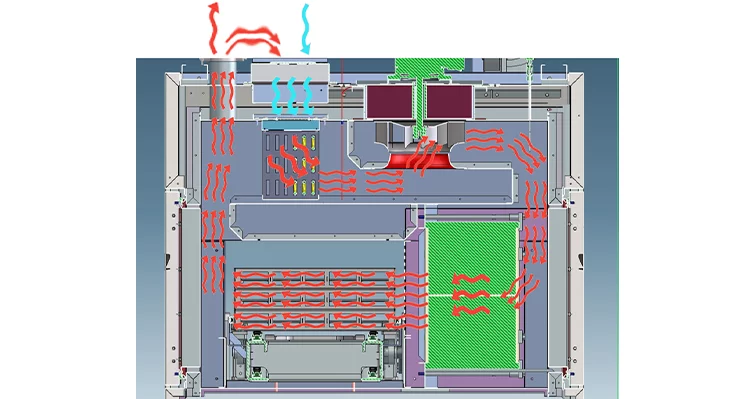

- The modular system has 3 individually controlled heating zones whose working temperature can be set independently of each other offering maximum process flexibility.

- Continuous furnace designed for curing of coatings on ophthalmic lenses.

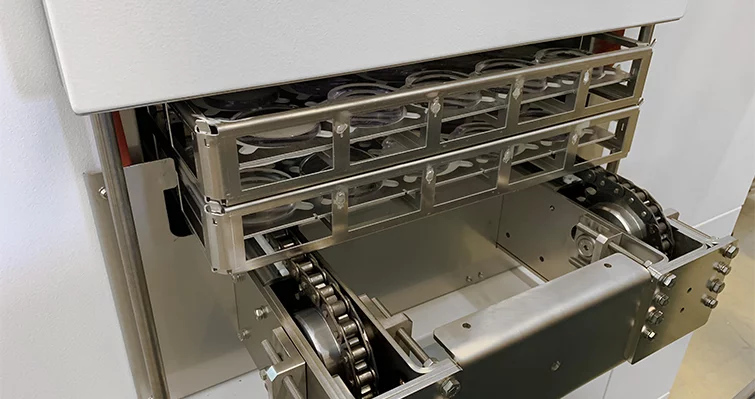

- For lens trays that can be stacked on up to 3 layers. There is space for a maximum of 12 trays in a row in the furnace. A maximum of 36 trays can thus be processed at once in the continuous furnace.

- The continuous furnace meets the requirements according to class ISO 6 (according to DIN EN ISO 14644-1) with built-in HEPA circulating air filters.

- The conveying speed can be set variably (10mm/min to 50 mm/min), as can the working temperature (up to 130° C).

- The modular continuous furnace consists 3 modules, divided into 3 regulated heating zones (inlet, outlet and middle module. Each with heating and control zone).

- Modular design of the system which allows different furnace setups (number of modules / conveyor length).

- Equipped with a state-of-the-art PLC controller with 7” touch panel. Siemens Simatic S7-1513 with colored touch panel available on option.

- Construction and equipment of the cleanroom furnace are either CE or UL compliant

System advantage

- Continuous workflow in small batches

- Process time savings and energy savings because of missing heat up and cool down periods

- The working temperature can be set individually in each zone which allows to run defined temperature profiles

- High consistency of the temperature (+/- 3K) resulting in stable coating quality

- Higher yield because of cleanroom condition according to ISO 6

- Low temperature emission into the environment due to highest isolation standard

- Easy maintenance and accessibility due to maintenance flaps on both sides

- Scalable productivity due to stackable lens trays (1 to max. 3 trays stacked)

- Various applications and processes possible

Process characteristics

Controller and Software:

- Built-in controller: S!MPAC controller with colored 7“ touch panel. Siemens Simatic S7-1513 with colored touch panel available on option.

- Displayed data: e.g. working room temperature of each heating zone (setpoint and actual value), conveying speed, program name, program status and more.

- Programming: A total of up to 100 different programs can be saved

- The controller is housed in the separately placed control cabinet

- Control cabinet dimensions: 1200x400x2200mm (WxDxH)

- Control cabinet weight approx. 150kg