Exhaust Scrubber Unit (ACC92)

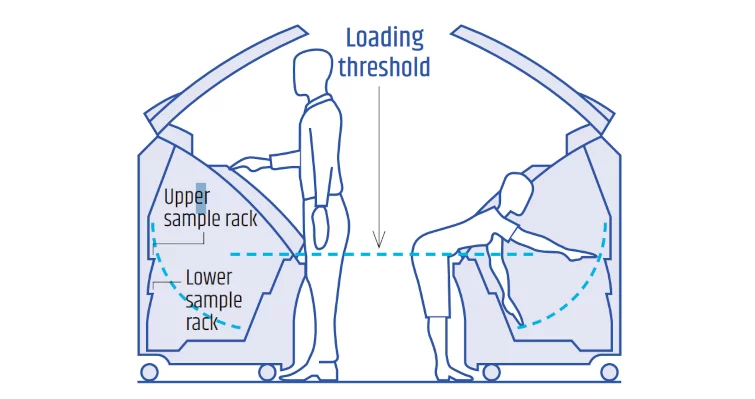

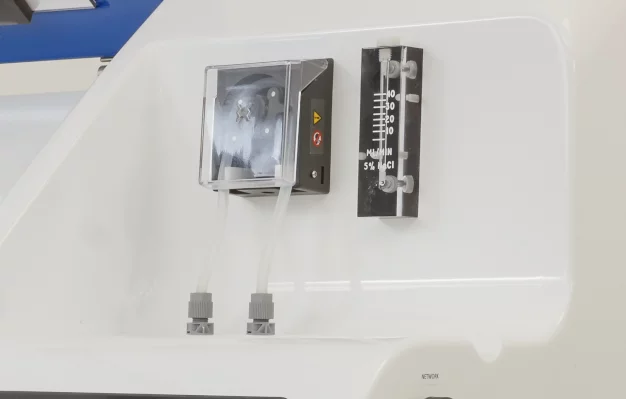

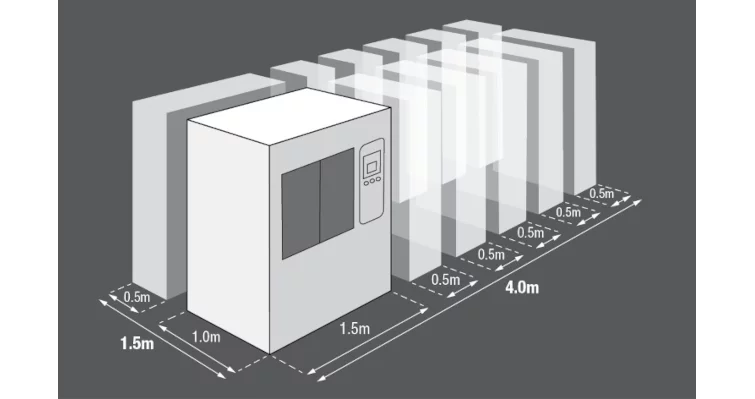

Designed to remove highly corrosive salt fog from the chamber exhaust, in chamber installations where it is either not convenient or not possible to allow the chamber exhaust to ventilate freely to atmospheric pressure outside the building.