Access Port 35/110mm (ACC10)

A 35mm (1.27") or 110mm (4,33") diameter sealable chamber access port. Passes through the left-hand wall of the chamber to enable the connection of external monitoring/driving equipment.

|

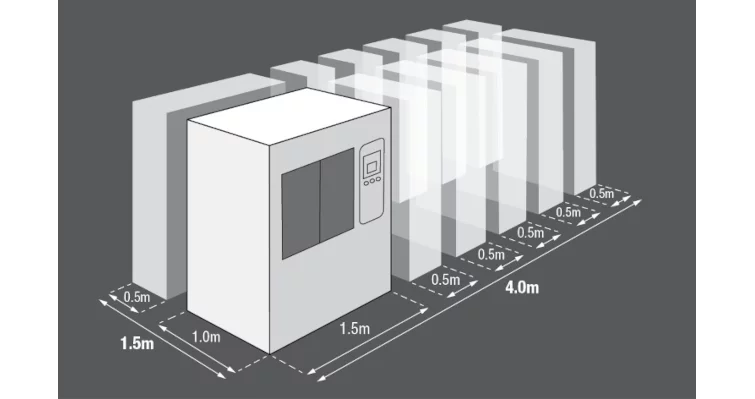

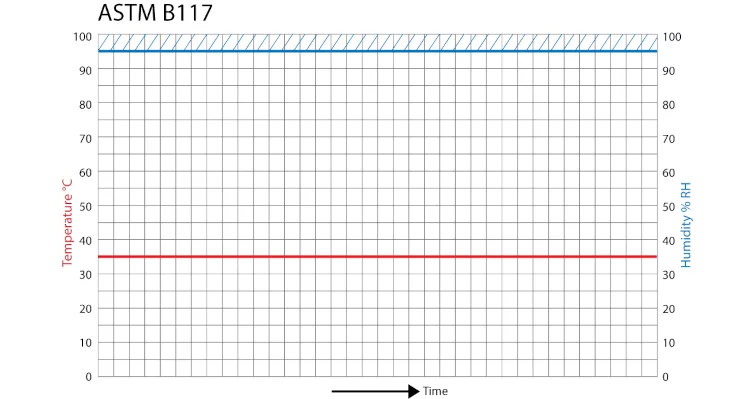

In response to customer demand for larger test chambers to test large samples, in a wide variety of shapes, sizes and weights, Ascott manufacture the CorroFlex, flexible size corrosion chamber. CFS models are salt spray only test chambers and can perform single temperature, continuous salt spray tests in accordance with international standards such as: ASTM B117, ISO 9227, JIS Z 2371 and many more. |

Chamber width and depth can be configured in 0.5 m increments. Ideal for testing large or irregularly shaped specimens.

Pneumatically operated door opens vertically. Saves space and simplifies loading/unloading.

Fresh air purge after testing to prevent salt fog escape. Interior lighting and viewing window for sample monitoring. Corrosion-resistant outer shell and easily accessible brine tank.

A huge range of accessories available so the customer really gets the chamber they want to suit their application and are not buying any redundancy.

Easily accessible salt spray atomizer(s) in transparent hard-wearing acrylic, for ease of maintenance.

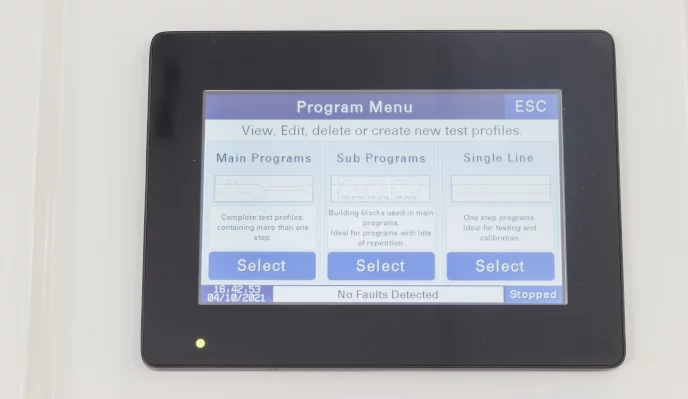

The Ascott iP test chambers can be pre-programmed for test standards in the factory, they are very easy to programme and start running.

High load capacity (up to 500kg) mesh racking. With test space Illumination.

High strength GRP panel front door. Pneumatically operated for ease of opening and closing (door slides up to close and down to open). With centrally located viewing windows for good visual access to chamber interior and test samples when door closed.

Timed canopy lock and purge of the chamber interior with fresh air after testing and before the chamber is opened, preventing corrosive salt fog escaping.

Silicone rubber encapsulated electrical heating mats are strategically bonded to the outside surfaces of the bottom and sides of the inner working chamber. Here they radiate heat uniformly into the chamber, under the control of the chamber temperature controller. In the salt spray mode of operation, these heaters give the chamber a user adjustable temperature range from ambient to +50°C/122°F.

Ergonomically positioned control unit for convenient and intuitive operation. Full-colour touchscreen interface with multi-language function and on-screen graphic of chamber temperatures.

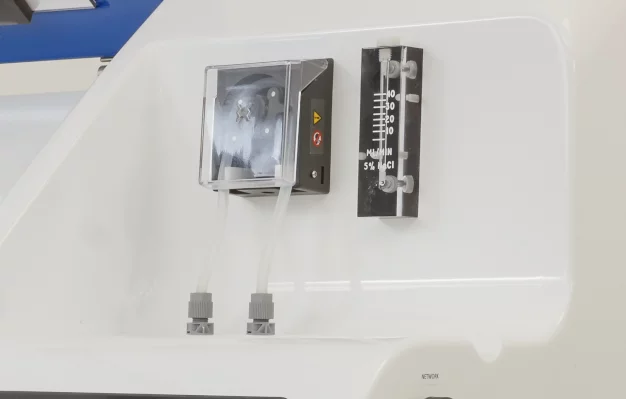

One 250L salt solution tank is provided for ease of filling and cleaning, one tank for the standard atomiser. All reservoirs incorporate a transparent graduated sight glass for ease of monitoring the solution level inside. During salt spray testing, the salt solution (brine) is drawn from this reservoir by the chamber peristaltic pump, via a primary filter unit which removes any large undissolved salt crystals or other debris.

During salt spray testing, the peristaltic pump draws salt water into the chamber from the separate salt solution tank, so avoiding the need for a gravity fed system. This salt water is delivered, via a graduated flowmeter, to the salt spray atomiser inside the chamber. The speed of the pump is fully adjustable by the user, to allow the quantity of salt solution atomised and hence the fall-out rate, to be precisely controlled.

This is a specially designed salt spray atomiser, to guarantee a uniform salt spray fall out which features an integral filter to minimise blockages. During salt spray testing, it is here that the compressed air, delivered via the air saturator, meets the salt solution, to create a fine salt spray (also referred to as 'salt mist' or 'salt fog').

As the CorroFlex name implies, these corrosion test chambers offer the user flexibility in specifying the perfect size of chamber to suit their application. The internal width and depth dimensions are variable and can be selected in 0.5m increments.

|

Water: Deionized/distilled for topping up air saturator and making salt solution. Air saturator requires a continuous water connection 2.5-5.0 bar (36-73 psi). If air saturator is topped up manually option ACC66 must be ordered.

|

|

Air: Clean dry & oil free, 4.0 to 6.0 bar (58-87psi) with 440 Ltrs (15.5cu.ft) per minute flow.

|

|

Exhaust: 3m (10ft) exhaust pipe is required which should be terminated outside building (see accessory ACC58).

|

|

Drain: 3m (10ft) drain pipe is required which should be terminated into floor level drain (see accessory ACC58).

|

|

Operating environment conditions: Indoors, with ambient maintained at +18 to +23°C (+64 to 73°F), 85% max RH (non-condensing).

|

| Testspace volume (l) | 1600 | |||

| Test Space Dimensions (H x W x D) (mm) | 1245 x 1500 x 1000 | |||

| External Dimensions (HxWxD) [mm] | 2230 x 2652 x 1300 | |||

| Test chamber door dimensions (mm) | 791 x 1176 | |||