MIL-STD-810 - The ideal support from Weiss Technik

Factsheet

MIL-STD-810 is a comprehensive standard developed by the U.S. Department of Defense for environmental engineering considerations and laboratory testing. It contains guidelines for testing mainly military equipment, electronics and components in the aerospace industry under various environmental conditions to ensure reliability and durability in harsh environments. The standard covers methods for testing the effects of temperature, humidity, vibration and altitude on equipment. The focus is on adapting the test procedures to specific equipment and application profiles to ensure that the tests are relevant and effective. Many standards can be met with testing equipment from weisstechnik.

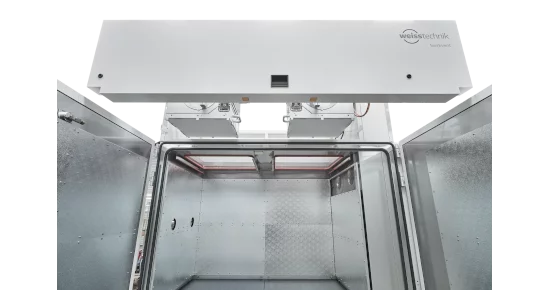

We offer the right solution for every test specimen – from compact bench-top models with 16 liters of test chamber volume, to reach-in test chambers, to drive-in systems for large-volume applications. In addition to our standard products, we work with our customers to develop customized solutions that are precisely tailored to specific requirements.

MIL-STD-810 is used wherever technical equipment must withstand extreme environmental conditions. Weiss Technik supports companies in developing and qualifying their products in accordance with standards, using high-precision testing technology – from electronic components to complex systems.

From avionics systems and onboard electronics to satellite components, products used in aviation must withstand pressure changes, temperature fluctuations, vibrations, and radiation. MIL-STD-810 provides the basis for the qualification of these components.

Military equipment must meet the highest standards of reliability under extreme conditions – from the desert to the Arctic, from jumping out of aircraft to transport in armored vehicles. MIL-STD-810 serves as the authoritative testing standard in this context.

Typical test specimens: Communication systems, vehicle electronics, portable equipment, sensor technology

Electronic components for outdoor and industrial applications must remain functional at all times – even when exposed to heat, moisture, corrosion, or mechanical stress. MIL-STD-810 ensures operational readiness even in extreme scenarios.

Typical test specimens: Control units, displays, IoT components, embedded systems

Modern vehicles – especially in a military context – are high-performance rolling systems. Tests according to MIL-STD-810 help validate the resistance of electronics and mechanics to environmental influences.

Typical test specimens: Control devices, camera systems, displays, vehicle components

In civil and military telecommunications, devices are often used outdoors – in regions with extreme climatic conditions or in mobile operations. MIL-STD-810 defines realistic scenarios for testing these systems.

Typical test specimens: Radio equipment, mobile communications technology, network components, base stations

Electronic systems, materials, and housings are often exposed to extreme cycles—from arctic cold to tropical heat and sudden temperature changes during flight or vehicle operation. The combination of static temperature and humidity tests and dynamic temperature shock simulates realistic environmental conditions. This allows condensation, material expansion, aging effects, and stress cracks to be detected as early as the development stage.

These tests are essential for manufacturers in the defense and aerospace industries, for automotive control units (civilian & military), industrial electronics, and for telecommunications and outdoor devices.

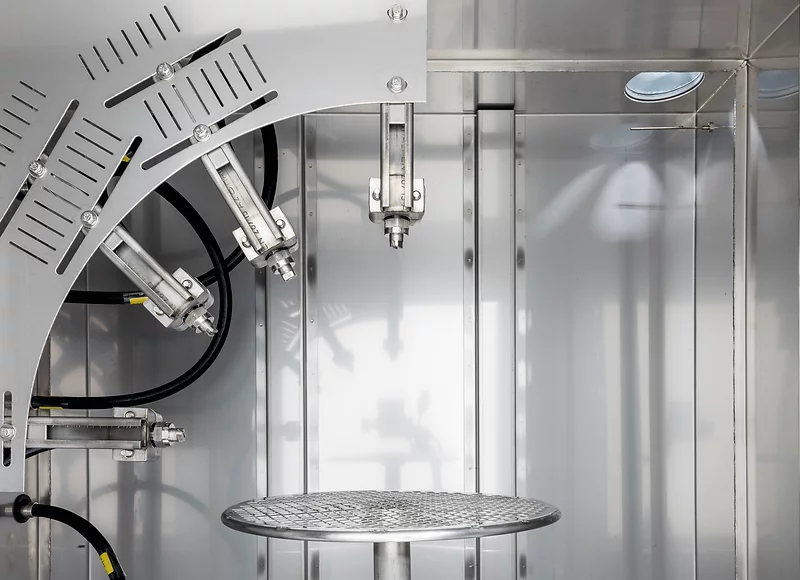

Penetrating water and aggressive liquids (oils, fuels, cleaning agents) can cause short circuits in electronics, accelerate corrosion, or damage seals. Water and liquid tests assess the sealing and protection concepts of enclosures, connectors, and assemblies under real-world operating conditions. Standardized test setups for tropical rain, direct jet water exposure, as well as short-term and prolonged liquid exposure are used for testing. Industries such as defense, aerospace, automotive (civil & military), industrial electronics, and telecommunications use these tests for displays, control units, sensors, pumps, and valves. The results help optimize enclosure designs and sealing systems for full functionality under water and liquid exposure.

Salt, moisture, and chemical aggressors attack metal structures, contacts, and sealing systems over time. Unprotected hardware can become inoperable within weeks, especially in marine, coastal, or industrial environments. To prevent this, corrosion tests accelerate aging processes and provide reliable information on the effectiveness of coatings, alloys, and sealing solutions.

MIL‑STD‑810 Method 509 defines salt fog and humidity chamber tests that realistically simulate salty and humid climates. Defense and aerospace manufacturers test structural components, connectors, and housings, as well as automotive components (civilian & military) and industrial electronics. Telecommunications providers test outdoor antenna locations and base stations to validate corrosion protection measures. Result: long-lasting product reliability and reduced maintenance cycles.

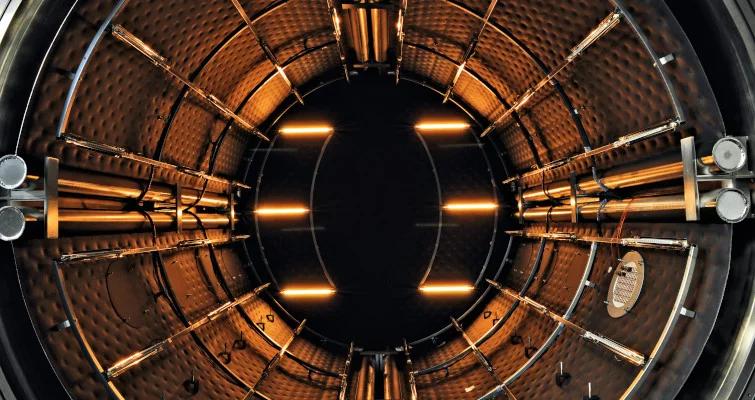

UV radiation, visible light, and infrared rays from the sun cause surface aging, color changes, embrittlement, and temperature hot spots. Solar simulation tests long-term stability and thermal stress caused by solar radiation.

MIL‑STD‑810 Method 505 specifies measurement parameters for spectrally correct radiation and intensity. Application in defense and aerospace projects, automotive exterior panels (civil & military), industrial outdoor installations, and telecommunications antennas. Enclosure materials, optics, sensor windows, and solar cells are tested for UV resistance, thermal stability, and embrittlement resistance, ensuring product quality in outdoor applications.

Dust, sand, and contaminated air particles can block fans, contaminate sensors, and cause heat build-up. Explosive or toxic atmospheres pose additional risks. Realistic particle testing is therefore essential.

MIL‑STD‑810 Method 510 (Dust/Sand) defines test chamber conditions for fine particle emissions. Defense and aerospace developers, automotive vehicle systems (civil & military), industrial installations, and telecommunications base stations are validated for particle tightness, filter efficiency, and explosion safety. This ensures system functionality even in desert, industrial, or urban operational environments.

At high altitudes or during rapid pressure changes (e.g., flight, mountain driving, UAV use), the ambient pressure drops, which can impair the functionality of seals, ventilation systems, and electrical components. Vacuum scenarios in aerospace and high-altitude research are also covered.

MIL‑STD‑810 Method 500 describes the simulation of altitudes up to 12,000 m and rapid pressure changes. Defense, aerospace, and UAV manufacturers, as well as automotive suppliers (civil & military) and industrial facilities, use this method to plan pressure tests for sensors, batteries, cable feedthroughs, and cooling systems. In telecommunications, high-altitude repeaters and weather stations are validated. Objective: Prevent vacuum lock, gas evolution in batteries, and seal failure.

Environmental conditions rarely occur in isolation: heat combined with humidity, temperature shock under low pressure, or vibration with sand exposure are typical combinations. MIL‑STD‑810 allows modular test sequences and special tests that realistically simulate complex operational scenarios.

Manufacturers in the defense, aerospace, automotive, industrial electronics and telecommunications industries use combined tests to validate complete system integration, whether for drones, armored vehicles, mobile command units, offshore base stations or space systems. Special methods such as MIL‑STD‑810 Method 502.6 (combined humidity) or customer-specific test procedures support customized requirements and ensure maximum availability under multiple loads.

Transport, shock loads during landing or combat situations, and constant vibrations during vehicle or aircraft operation place heavy demands on electronics and mechanics. Mechanical tests reveal possible fractures, loosening of connections, and material fatigue.

MIL‑STD‑810 Method 514 (Vibration) is relevant across industries for defense, aerospace, automotive (civilian & military), industrial electronics, and telecommunications. The tests cover printed circuit boards, connectors, displays, housings, mounting systems, and structural components. Results are incorporated into design optimizations and assembly guidelines to increase robustness.

Factsheet