Insulated roof blanket (ACC45)

|

An insulated non-transparent blanket for the transparent roof. Improves thermal efficiency to increase cabinet maximum operating temperature and salt spray fall-out range. |

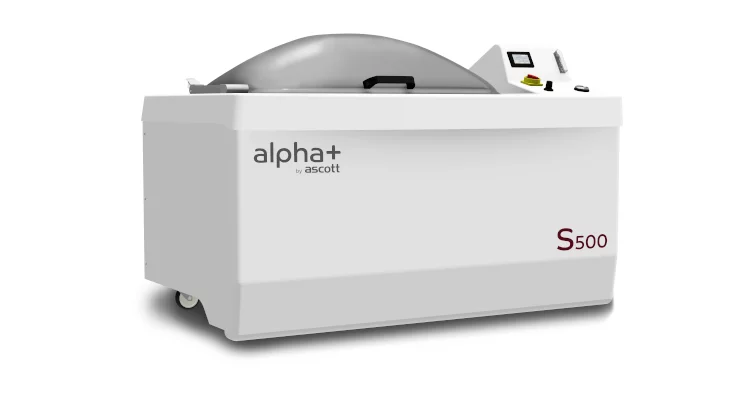

Alpha+ Salt Spray Testing Cabinets are designed to appeal to the modern test laboratory. They offer affordability and the equipment is easy to install, simple to operate and reliable in service. The Alpha+ S models are used for short-term tests. The Alpha+ SP models are used for long-term tests. Ascott defines short-term tests as tests with a duration of up to 240 hours. Tests that exceed this duration are defined as long-term tests.

Minimal number of external service connections

Intuitive colour touch screen interface

Uncomplicated design backed by 35 years manufacturing experience.

The Alpha+ range complies with the most popular international standards for corrosion testing, including: Salt spray standards.

Fully transparent and seamless domed roof, without welded/glued seams with 360° all-round visibility, self-supporting when open.

An automatically refilling water seal prevents salt mist from escaping from the appliance during the salt spray phase.

Robust construction made of glass fibre reinforced plastic (GRP), a durable, impact-resistant material with strong chemical and corrosion resistance that ensures a long service life.

Ergonomically positioned control unit for convenient and intuitive operation. Full-colour touchscreen interface with multi-language function and on-screen graphic of chamber temperatures.

SP salt spray chambers are equipped with an advanced control system that incorporates a peristaltic pump based salt water delivery system, coupled with a user adjustable precision speed controller to ensure consistent salt spray precipitation rates during unattended long term testing.

Air Saturator can be topped up with water automatically, or by hand via the manual filler port.

This is a specially designed salt spray atomiser, to guarantee a uniform salt spray fall out which features an integral filter to minimise blockages. During salt spray testing, it is here that the compressed air, delivered via the air saturator, meets the salt solution, to create a fine salt spray (also referred to as 'salt mist' or 'salt fog').

Standard models are designed for continuous salt spray tests, conducted at a single user-adjustable temperature, such as ASTM B117, ISO 9227, JIS Z 2371 etc. They may be used with pH neutral salt solutions (NSS) or test solutions acidified by the addition of Acetic Acid (ASS) or Cupric Acid (CASS).

SP models are equipped with an advanced control system featuring a peristaltic pump based salt water delivery system, coupled with a user adjustable precision speed controller.

Ensures consistent fall-out of salt spray / fog on to the test samples, over longer term duration tests (240+ hours of continuous salt spray testing) especially if such testing is unattended.

|

Water: Deionized/distilled for topping up air saturator and making salt solution. Air saturator requires a continuous water connection 2.5-5.0 bar (36-73 psi).

|

|

Air: Clean dry & oil free, 4.0 to 6.0 bar (58-87psi) with 240 Ltrs (8.5cu.ft) per minute flow

|

|

Exhaust: 3m (10ft) exhaust pipe is required which should be terminated outside building (see accessory ACC58).

|

|

Drain: 3m (10ft) drain pipe is required which should be terminated into floor level drain (see accessory ACC58).

|

|

Operating environment conditions: +18 to +23°C (+64 to 73°F), 85% max RH (non condensing) ambient

|

| ||||

|---|---|---|---|---|

| Testspace volume (l) | 500 | |||

| External Dimensions (HxWxD) [mm] | 1102 x 1650 x 934 | |||

| Test Space Dimensions (H x W x D) (mm) | 866 x 1076 x 683 | |||

| Current Rating (A) | 13 | |||