CO2 refrigeration units (ACC29)

A separate free standing air temperature and humidity conditioning unit (ATCU), capable of refrigerating a CCT chamber down to -20°C or -40°C.

Ascott cyclic corrosion chambers – one of the world’s most sophisticated and versatile corrosion test systems available, combining salt spray with other environmental conditions such as controlled humidity, drying and wetting. These may be programmed to occur in any sequence and be repeated automatically. A wide range of optional accessories enable additional climates to be added to further extend the number of climates and conditions that can be created.

Up to six different climate phases can be programmed and combined: Salt spray, Wetting (condensation), Forced air drying, Ambient drying, Controlled humidity, Temperature cycling

Every test item and test is different - available in range of different sizes. Over 100 accessories for customization (e.g. cooling units, immersion tanks, norm-specific setups)

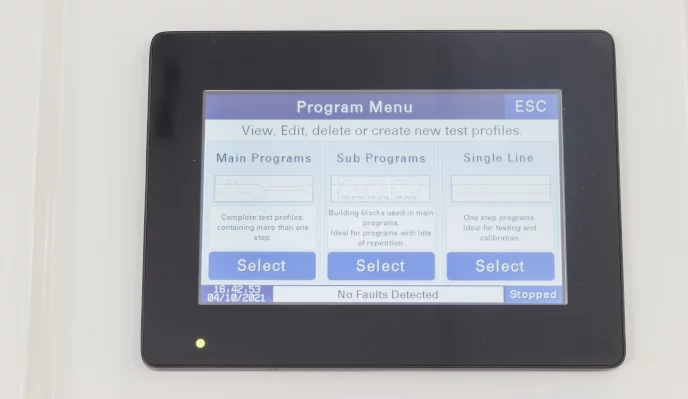

7" color touchscreen with intuitive interface. Storage for up to 254 complex test programs.

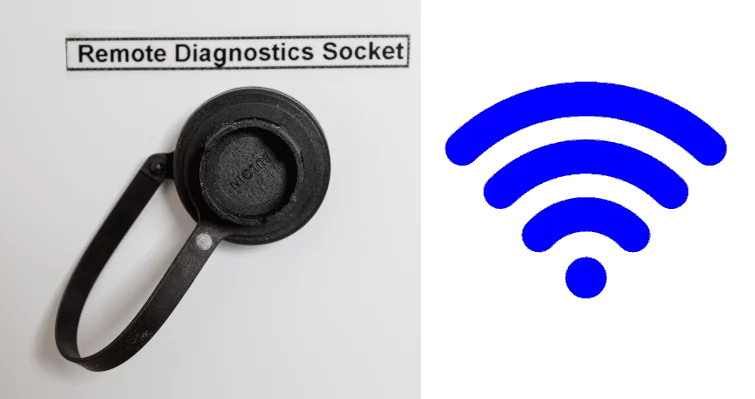

Remote access via LAN for monitoring and data logging and is compatible with control software S!MPATI from Weiss Technik

Pneumatic “Easy Open” canopy with safety lock. Dry seal to protect clothing. Automatic fresh air purge after testing. External salt solution tank for easy maintenance.

Now also available with CO2 Cooling according to EU F-GAS regulation 2024/573

Ergonomically positioned control unit for convenient and intuitive operation. Full-colour touchscreen interface with multi-language function and on-screen graphic of chamber temperatures.

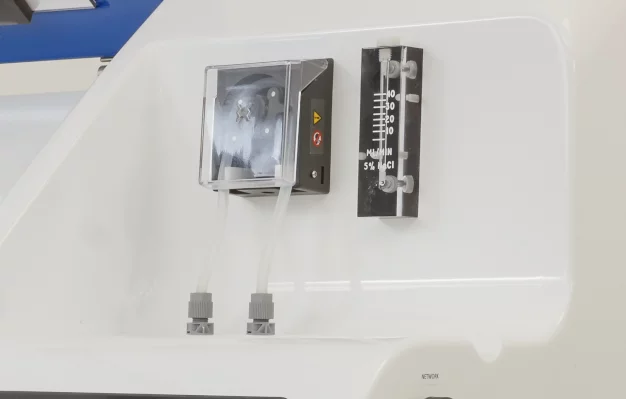

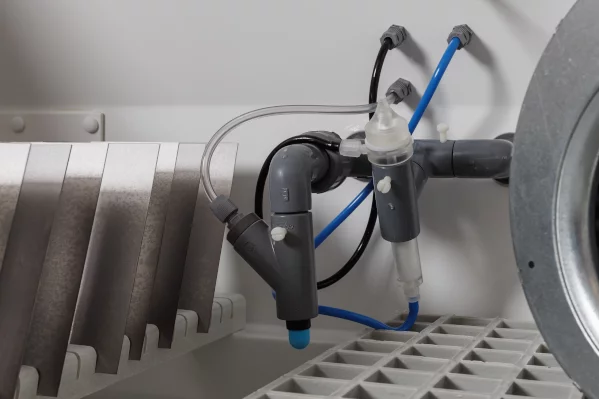

During salt spray testing, the peristaltic pump draws salt water into the chamber from the separate salt solution tank, so avoiding the need for a gravity fed system. This salt water is delivered, via a graduated flowmeter, to the salt spray atomiser inside the chamber. The speed of the pump is fully adjustable by the user, to allow the quantity of salt solution atomised and hence the fall-out rate, to be precisely controlled. Two pumps and flowmeters are fitted to 2000L/2600L size chambers.

RJ45 communications port for connection to a local area network (LAN) for logging and remote programming via a computer running optional Ascott software (ACC121). (iP only).

The chamber canopy is effortlessly opened/closed using pneumatic cylinders, which are activated at the touch of a button on the control panel. Canopy features a central viewing window to see the samples during test.

Dry seal gasket prevents wetting operator’s clothes, etc

An automatic purge of the cabinet interior with fresh air is incorporated to minimise the risk of corrosive salt spray escaping into the laboratory when the chamber is opened.

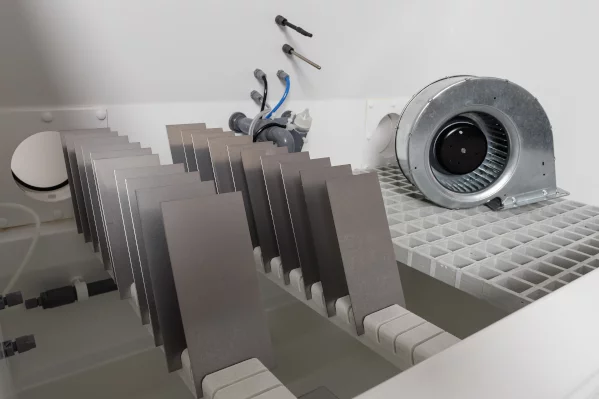

Corrosion-resistant test chamber made of Glass Reinforced Plastic (GRP). With easily accessible salt spray atomizer(s).

This is a specially designed salt spray atomiser, to guarantee a uniform salt spray fall out which features an integral filter to minimise blockages. During salt spray testing, it is here that the compressed air, delivered via the air saturator, meets the salt solution, to create a fine salt spray (also referred to as 'salt mist' or 'salt fog').

Ambient drying function to open/close the canopy during a test, exposing the samples to ambient conditions in the room.

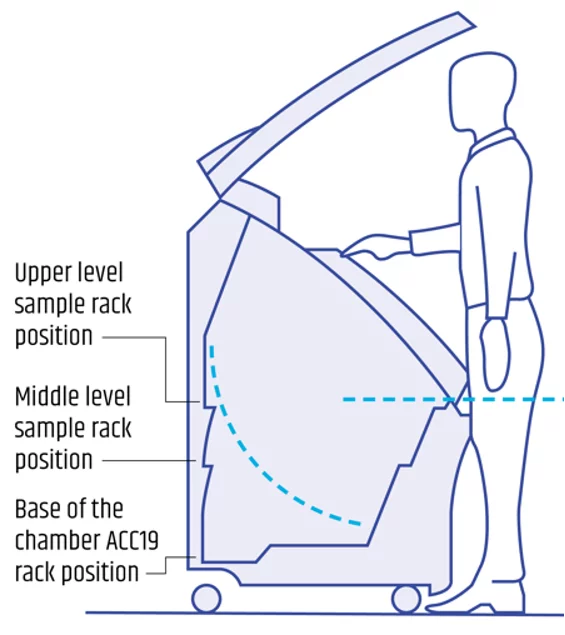

Low loading threshold for loading and unloading samples into the chamber. Three sample loading positions available. The chamber base, the middle level and the upper level.

This chamber is fitted with a state of the art electronic humidity sensor which measures the relative humidity inside the chamber and displays this at the HMI as %RH.

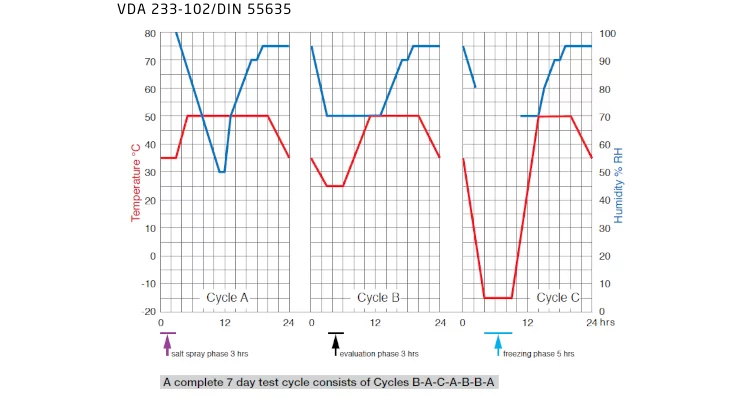

Cyclic corrosion testing (CCT) is designed to replicate the complex and changing environmental conditions that materials and coatings face in real-world applications. Unlike traditional salt spray tests, CCT involves alternating phases such as Salt fog exposure, Humidity and condensation, Drying cycles, Temperature fluctuations

This method is widely used in industries like automotive, aerospace, and construction to evaluate long-term durability under accelerated conditions.

Ascott Analytical’s chambers are among the most sophisticated systems for cyclic corrosion testing. They offer:

|

Temperature Range

|

Humidity Range | Salt Spray Fallout rates | |

|---|---|---|---|

| Wetting Mode | Ambient to +70°C / +158°F | 95% - 100% RH | N/A |

| Atomiser Salt Spray Mode | Ambient to +60°C / +140°F | N/A | 0.5 to 2.0ml per 80cm² per hour |

| Forced Air Drying Mode | Ambient to +70°C / +176°F |

N/A |

N/A |

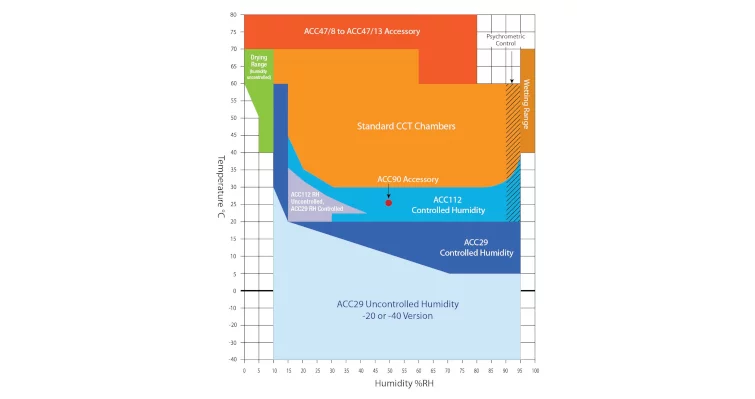

| Climatic Mode | See adjacent graph | See adjacent graph | N/A |

| Controlled Temperature Only Mode | Ambient to +60°C / +140°F | N/A | N/A |

| Ambient Air Drying Mode | Alters to laboratory ambient conditions | Alters to laboratory ambient conditions | N/A |

The above parameters can be extended with certain accessories. Please contact us for more informations!

|

Water: Deionized/distilled for topping up air saturator and making salt solution. Air saturator requires a continuous water connection 2.5-5.0 bar (36-72 psi). If ACC42 is ordered the continuous water supply must be pressuried 4.0 – 5.0 bar (58-72 psi). If air saturator is topped up manually option ACC66 must be ordered.

|

|

Air: Clean dry & oil free, 4.0 to 6.0 bar (58-87psi) with 440 Ltrs (15.5cu.ft) per minute flow.

|

|

Exhaust: 3m (10ft) exhaust pipe is required which should be terminated outside building (see accessory ACC58).

|

|

Drain: 3m (10ft) drain pipe is required which should be terminated into floor level drain (see accessory ACC58).

|

|

Operating environment conditions: +18 to +23°C (+64 to 73°F), 85% max RH (non condensing) ambient.

|

| ||||

|---|---|---|---|---|

| Testspace volume (l) | 450 | |||

| Test Space Dimensions (H x W x D) (mm) | 1140 x 1010 x 640 | |||

| External Dimensions (HxWxD) [mm] | 1510 x 1660 x 840 | |||

| Salt Solution Reservoir Capacity (l) | 73 | |||

| Total Weight (kg) | 190 | |||

| Voltage Rating | 3/N/PE AC 400 V ±10 % 50 Hz | |||