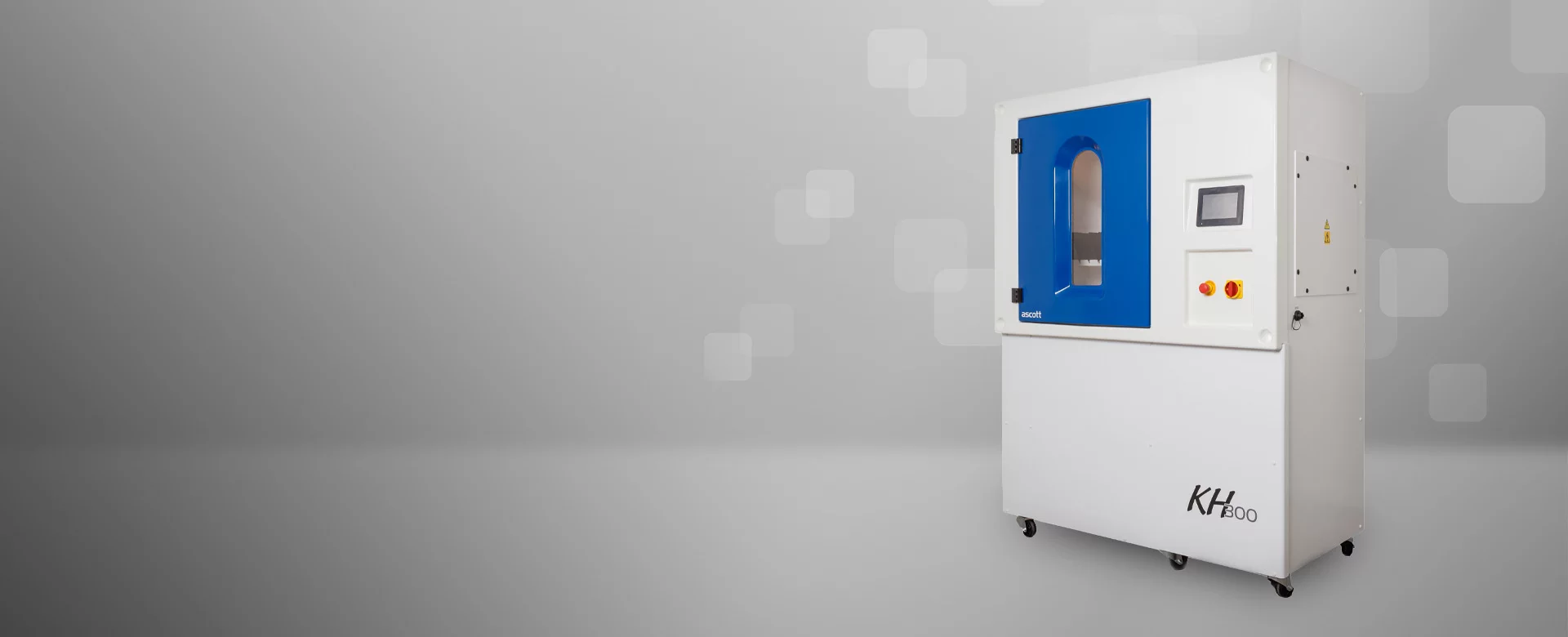

SO2 Humidity Chamber

Kesternich testing simulates acid rain or industrial chemical exposure to evaluate the relative corrosion resistance of the coating, substrate, or part itself. Parts or panels are placed inside a specially designed chamber and are exposed to SO2 and condensation humidity before being evaluated for resistance to corrosion.

That makes the Kesternich Chamber unique.

Fully automatic operation

No manual intervention required during the tests

Multifunctionality

In addition to SO₂ tests, can also be used as a pure condensation humidity chamber

Precise control

Modern electronic gas dosing system and digital temperature control

Safety features

Hermetically sealed chamber, automatic air purging, pneumatic hood control

Space-saving options

Also available as a tabletop unit

User-friendliness

Intuitive controls, graphic temperature display, Ethernet connection

Explore the Kesternich Chamber.

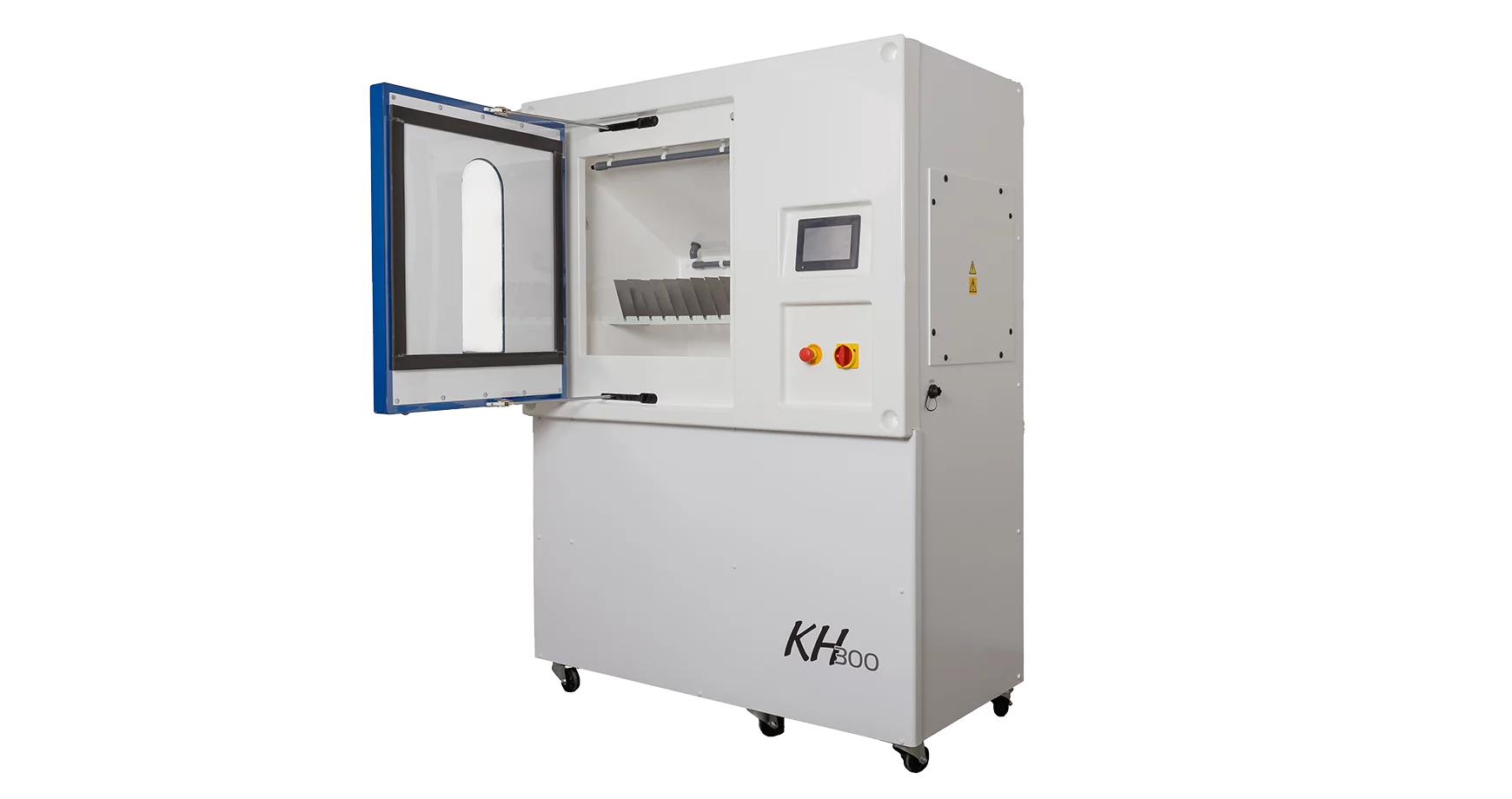

Pneumatic canopy ram

Timed canopy lock and purge of the chamber interior with fresh air after testing and before the chamber is opened, preventing SO2 gas escaping.

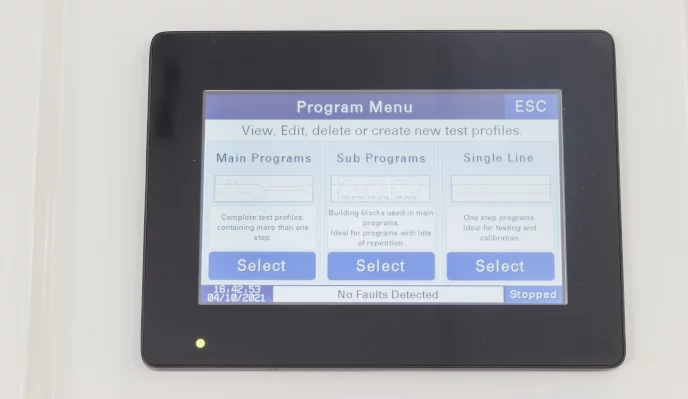

Touchscreen Controller

Ergonomically positioned control unit for convenient and intuitive operation. Full-colour touchscreen interface with multi-language function and on-screen graphic of chamber temperatures.

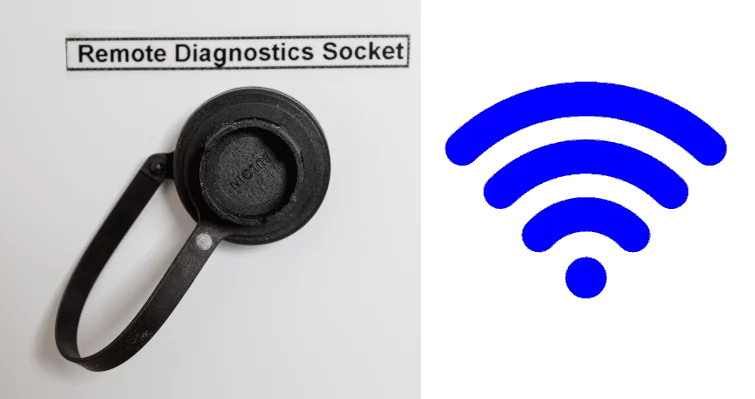

Communication port

RJ45 communications port for connection to a local area network (LAN) for logging and remote programming via a computer running optional Ascott software (ACC121).

Dry seal gasket

Dry seal gasket prevents wetting operator’s clothes, etc

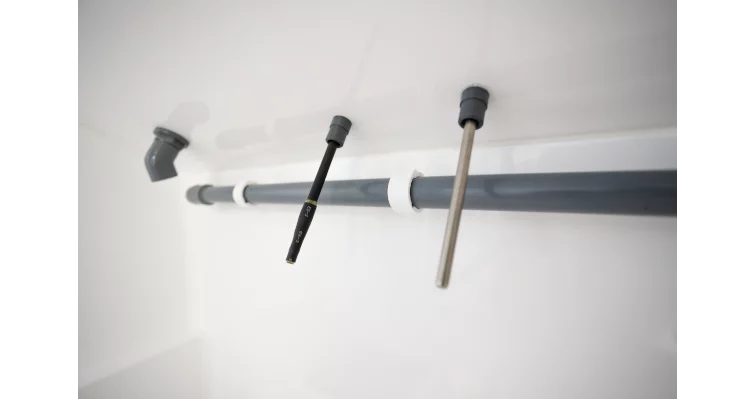

S02 dispersion bar

Fully automated electronic gas dosing system.

Air distribution bar

For purging and the air drying function.

Test space illumination

The inside of the test space can be illuminated at the touch of a button.

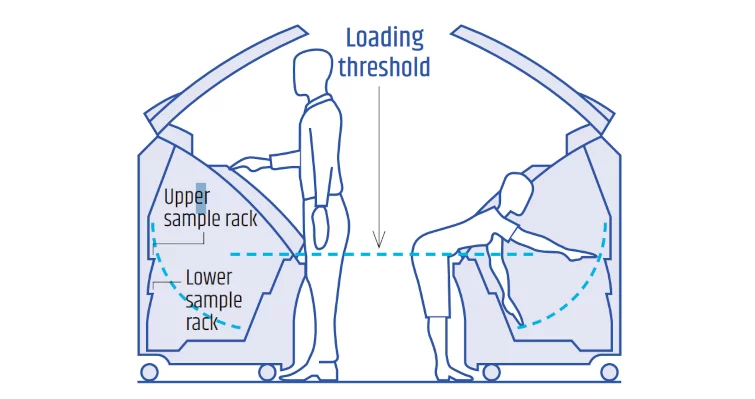

Low loading threshold

Low loading threshold for loading and unloading samples into the chamber

Chamber Connection

The following connections can be found on the back of the chamber: Mains power lead, remote diagnostic socket - Connection to the chamber, compressed air connection, Sulfur dioxide inlet, drain for change the paraffin system, water inlet

Well-designed test room

Chamber designed with angled interior roof to avoid condensation droplets falling onto samples below.

Video

Fully Automatic, SO2 Gas Dosing Test Chamber.

A specific volume of SO2 gas, usually 0.2L, 1L or 2L is introduced into the test chamber, the chamber temperature is increased to a predetermined level and the relative humidity is maintained at condensation levels. After a set period, the chamber is vented and the temperature is allowed to decrease to ambient conditions.

Ascott’s Kesternich chamber does not require any human intervention whilst running the tests, its fully automatic design is controlled by a state of the art control system. The Kesternich chamber is designed to meet various gas dosing test standards as listed below and can also be used as a condensation humidity chamber.

Discover the advanced user interface of the Ascott Kesternich SO₂ Humidity Chamber in action.

This video offers a detailed look at the innovative touchscreen control system of the Ascott Kesternich SO₂ Humidity Chamber. The intuitive interface allows users to easily configure and manage all test parameters — including SO₂ gas dosing, humidity control, air purging, and drainage — all fully automated.

Designed for efficiency and repeatability, the system ensures consistent and accurate corrosion testing results. Watch the video to see how effortless and effective test setup and operation can be with the latest control technology.

Video

Fully complies with the following standards.

| ASTM D2247 | NFT 30-077 | |

| ASTM G87 | ISO 6270-2 CH | |

| SFW 2,0,S | ISO 22479 | |

| ISO 3231 | VDA 621-421 | |

| ISO 11503 | NFT 30-055 | |

| BS3900/F9 | EN ISO 6988 | |

| ISO EN 1096 B | DIN 50017 KK & KTW | |

| DIN 50018 | ISO EN 1096 C |

Installation requirements.

|

Water: Deionized/distilled for topping up humidity generator.

|

|

Air: Clean dry & oil free, 4.0 to 6.0 bar (58-87psi) with 240 Ltrs (8.5cu.ft) per minute flow

|

|

Exhaust: 3m (10ft) exhaust pipe is required which should be terminated outside building (see accessory ACC58).

|

|

Drain: 3m (10ft) drain pipe is required which should be terminated into floor level drain (see accessory ACC58).

|

|

Operating environment conditions: Indoors, with ambient maintained at +18 to +23°C (+64 to 73°F), 85% max RH (non-condensing).

|

Technical Data

| ||

|---|---|---|

| Testspace volume (l) | 300 | |

| Test Space Dimensions (H x W x D) (mm) | 855 x 711 x 601 | |

| External Dimensions (HxWxD) [mm] | 2100 x 1478 x 769 | |

| Voltage Rating | 1/N/PE AC 230 V ±10 % 50 Hz | |

| Sound Pressure Level (dB(A)) | 69 | |