RTCA DO-160 - The ideal support from Weiss Technik

Factsheet

Test requirements for electrical and electronic equipment in aerospace systems

RTCA DO-160 is a key test standard for environmental and electromagnetic compatibility (EMC) testing. It was developed by the Radio Technical Commission for Aeronautics (RTCA) in order to ensure that aviation equipment operates reliably under the typical and extreme conditions of flight operations. The standard comprises a range of test procedures for factors such as temperature, altitude, vibration, humidity, lightning strike, and electromagnetic interference. Under DO-160, devices are classified into categories that vary depending on the installation location in the aircraft and the operational profile. This ensures that the tests are practical and tailored to the specific use case. Many DO-160 test procedures can be carried out using testing equipment from weisstechnik.

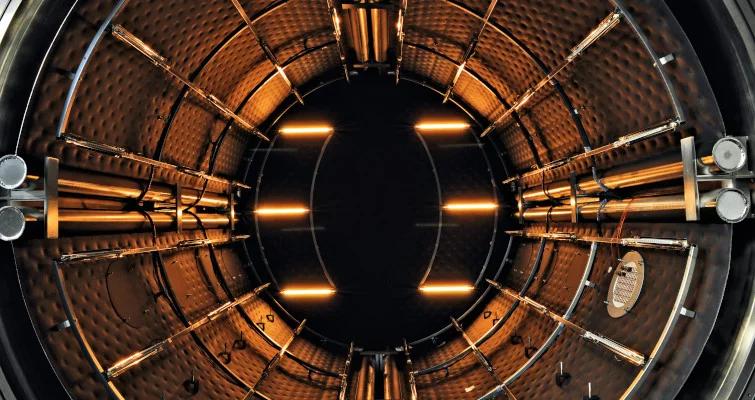

For each test item, we offer the right solution: from compact bench-top models with a 16-liter test chamber volume to reach-in test chambers to drive-in systems for large-volume test items. In addition to our standard products, we work closely with our customers to develop customized solutions precisely tailored to their specific requirements.

Nice to know: RTCA DO-160 is recognized worldwide by aviation authorities such as the CAA, FAA, EASA, and Transport Canada. Proof of conformity is often a prerequisite for the certification of aircraft and the issuance of airworthiness certificates.

RTCA DO-160 is used to ensure the reliability of airborne equipment under environmental conditions. Using high-precision testing technology, Weiss Technik GmbH supports companies in the standards-compliant development and qualification of their products.

Manufacturers of avionics, onboard electronics, and cabin systems must comply with DO-160 because this forms the basis for certification in commercial aircraft.

Typical test items: flight management systems (FMS), cockpit displays (PFD, MFD), transponders, ADS-B devices, cabin lighting, PSU modules, and in-flight entertainment (IFE) systems.

Also military aircraft frequently use RTCA DO-160, particularly when commercial-off-the-shelf (COTS) components from the civil market are adapted.

Typical test items: navigation equipment and mission computers, communication systems (e.g., UHF/VHF radios), and military UAV electronics (e.g., electronics bays, power supply units).

Manufacturers of electric air taxis and drones for passenger transport or delivery purposes follow DO-160 in order to demonstrate electromagnetic compatibility, vibration resistance, and battery safety.

Typical test items: eVTOL flight control computers, battery management systems (BMS) for aircraft, high-voltage inverters, and electric motor control units

Professional drones used for inspections, surveying, or government missions are increasingly aligned with DO-160 in order to ensure reliability and airspace approval.

Typical test items: autopilots for UAVs (e.g., Pixhawk-based aviation variants), GNSS receivers for UAVs, and telemetry and radio modules

Although there are specific spaceflight standards (NASA, ESA), DO-160 is used for components deployed in both aviation and space applications or when previous testing according to DO-160 is already considered valid.

Typical test items: electronic subsystems for small satellites (CubeSats), power supply modules, and communication transceivers

Helicopters generate extreme vibrations and temperature fluctuations. DO-160 is therefore a standard requirement for all electronic systems used.

Typical test items: helicopter avionics, rotor monitoring systems, GPS trackers, and emergency locater transmitters (ELTs)

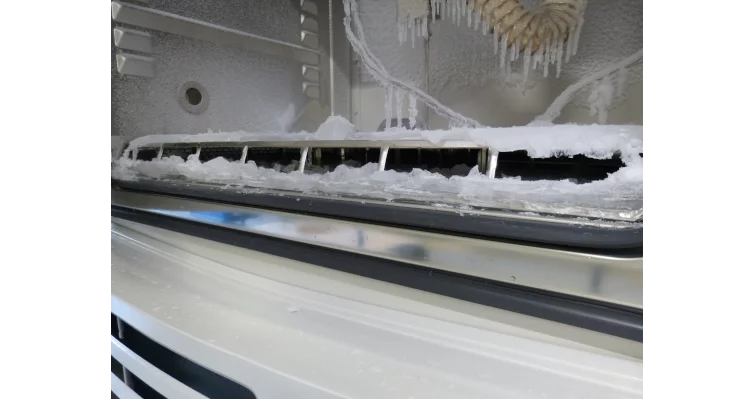

Aviation devices are often exposed to abrupt and repeated temperature changes (e.g., during rapid altitude changes, transitions between air-conditioned and non-air-conditioned areas, or installation in external locations). The temperature fluctuation test according to RTCA DO-160G Section 5 simulates these real-world stress scenarios through cyclic testing between defined operating limits.

The objective is to evaluate the effects of thermal stress on materials, enclosures, electronic components, and interfaces. The focus is on thermally induced stresses, material fatigue, crack formation, condensation, and functional deviations. Rapid temperature gradients are particularly critical because external and internal components heat up or cool down at different rates.

Factsheet