System consulting and planning

As system room specialists, we provide expert, customized consulting and planning. In doing so, we take into account legal requirements, practical needs, and economic factors.

Hydrogen fuel cells and electrolyzers can help substantially reduce CO₂ emissions. To ensure lasting performance and safety, they are manufactured under controlled, particle-free conditions with precisely defined humidity and temperature and then tested in a measurement room.

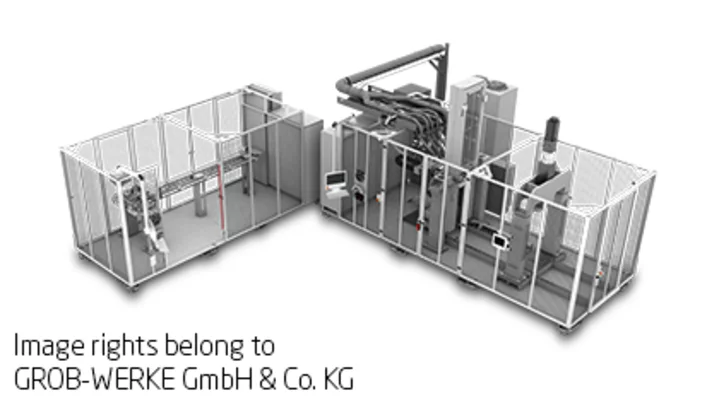

As a specialist in advanced process climate control and custom system rooms such as cleanrooms, measuring rooms, clean areas, and mini-environments, we design and deliver complete, reliable solutions all from a single source.

Even the smallest airborne particles can disrupt the production process of fuel cells and electrolyzers. With filters, personnel and material airlocks, advanced ventilation systems, and pressure cascades, we ensure that the required particle cleanliness is reliably maintained at all times.

In addition to air cleanliness, stable environmental conditions are essential for the production of fuel cells and electrolyzers. Our climate control technology keeps temperature and humidity within the defined tolerance range, thereby ensuring stable production conditions at all times.

The production of components for the hydrogen industry is a sensitive process. For reasons of quality and safety, all process parameters must be continuously monitored and documented. We design and implement advanced, needs-based monitoring solutions for this purpose.

Although system rooms are energy-intensive by nature, they are indispensable for the production of fuel cells and electrolyzers. Using innovative technologies and smart design solutions, we ensure that system rooms operate as efficiently as possible.

We specialize in advanced and energy-efficient climate control technology for system rooms. Whether as new builds, conversions, or extensions of existing system rooms, we tailor the design and implementation according to the specific needs and requirements of the customer.

Our climate control systems filter and condition the air precisely to meet process requirements. After passing through multiple filtration stages, the air is directed into the controlled room and supplied to ensure uniform distribution over time and space. A contamination monitoring system continuously tracks particle size and count, temperature, and humidity in the production environment. If a defined threshold is exceeded, an alarm is automatically triggered.

Whether for the production of hydrogen fuel cells, electrolyzers, or other sensitive applications, we provide tailored solutions for controlled environments with precisely defined temperature and humidity.

Industry brochure

Download